Bringing the power and

versatility of AFM

technology to everyone

Park SmartScan is a revolutionary operating software

for Park AFMs that lets even inexperienced,

untrained users produce high quality nanoscale

imaging through three simple clicks of a mouse in

auto mode, which rivals that made by experts using

conventional techniques.

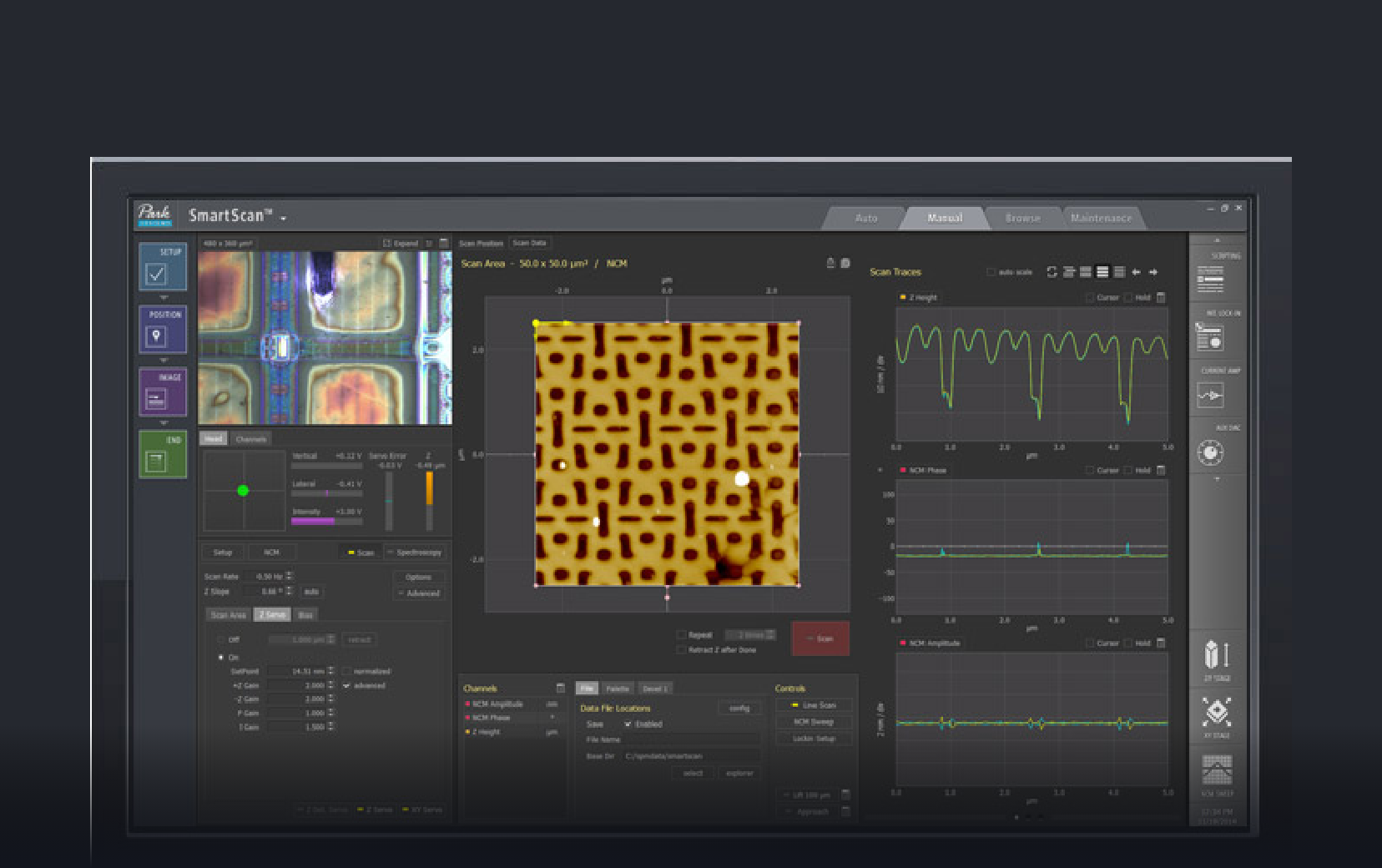

SmartScan manual mode also provides all of the

functions and tools necessary for more seasoned

users to feel at home. This combination of extreme

versatility, ease-of-use, and quality makes SmartScan

the best AFM operating software available.

Combining power and

simplicity

Most AFMs require complicated operation by the

user. Park SmartScan doesn't. All that's needed

from the user are three automated clicks, with

animated instructions for setup anyone can

understand. But if you want more control, the

system offers a comprehensive set of functions

and parameter settings.

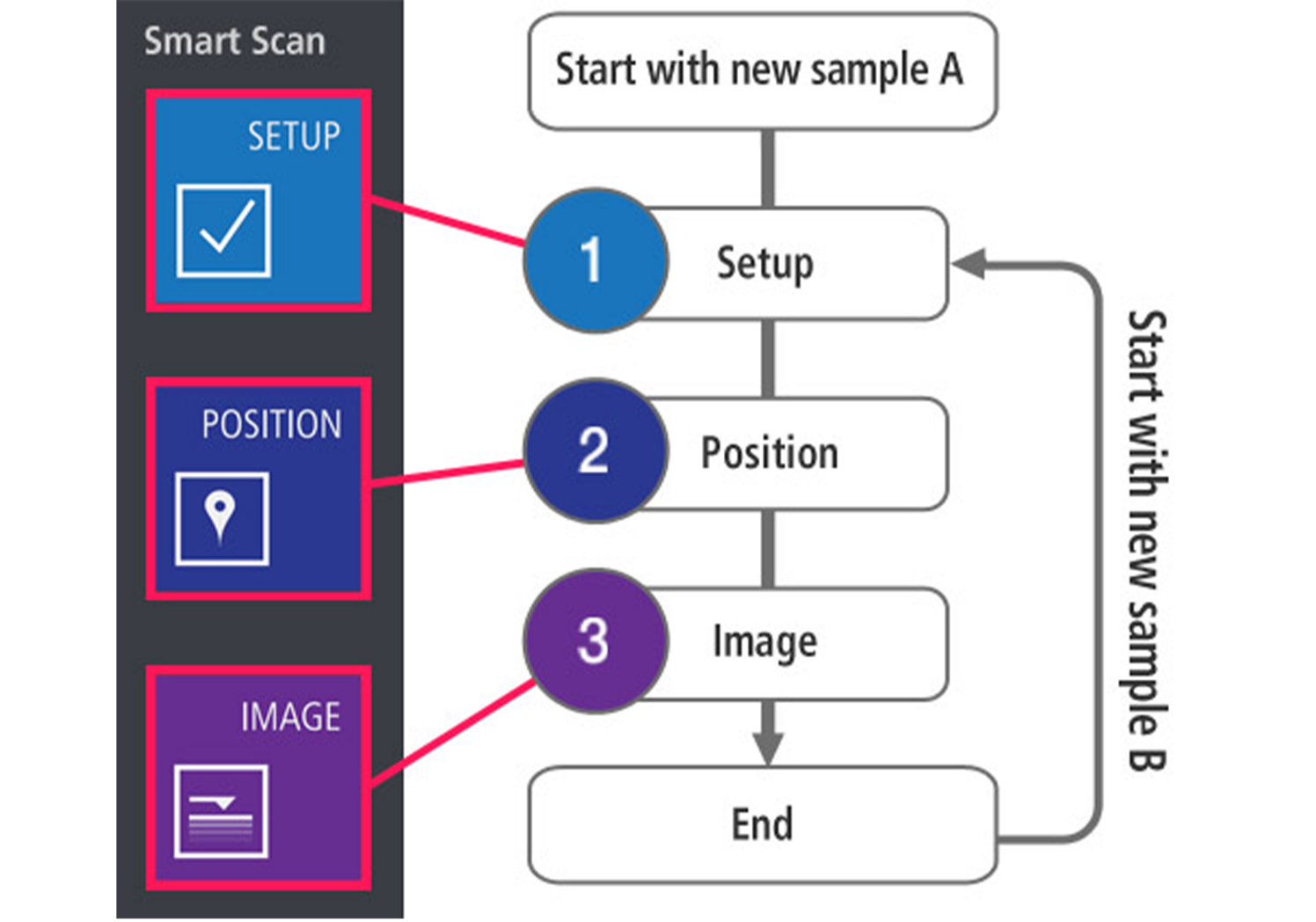

Here is how it works after you turn

on the AFM system

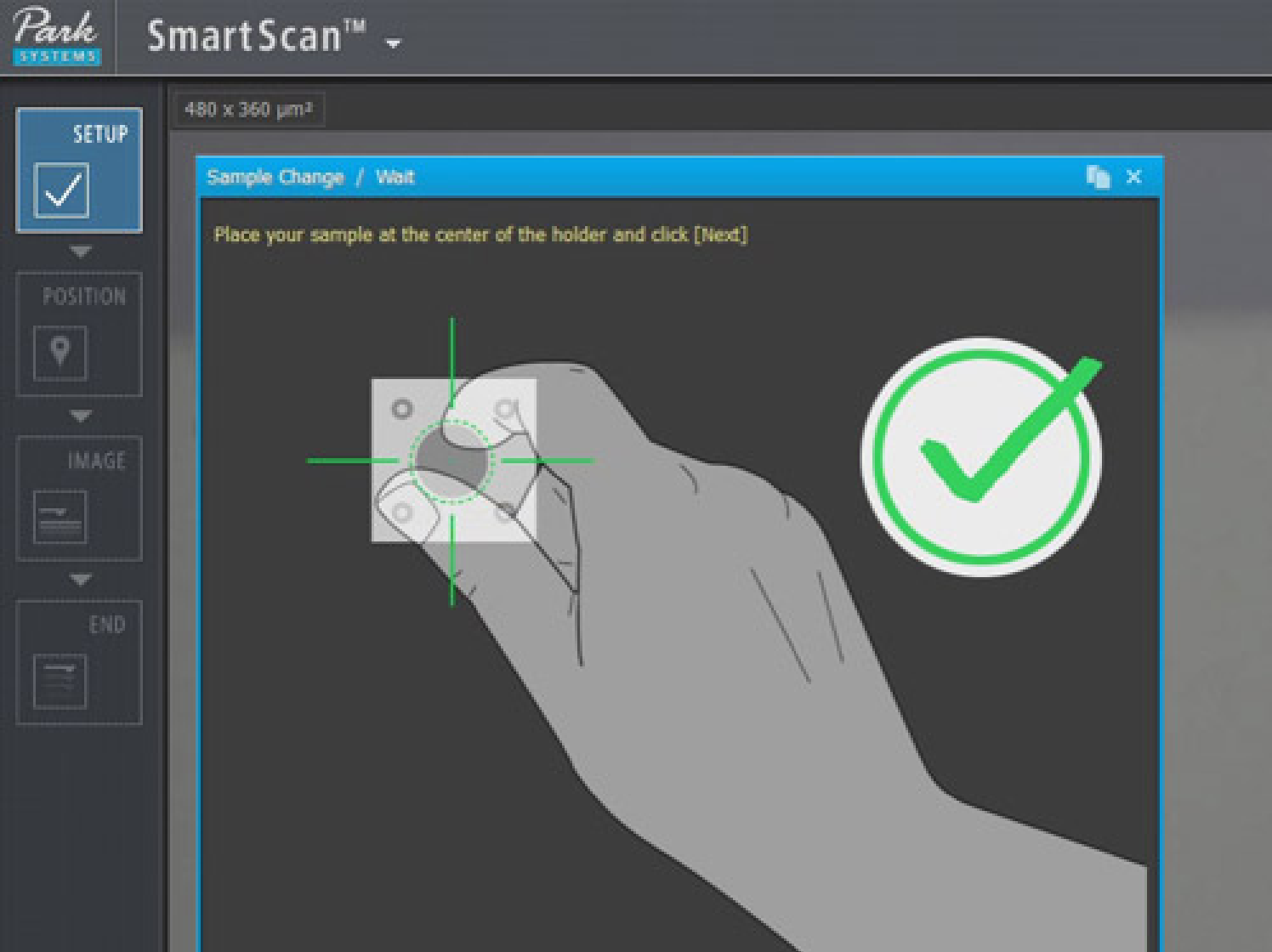

1 “Setup”

A small window guides you through animation to

set the instrument and place the sample for imaging.

Typically, this only takes a few minutes.

2 “Position”

The system automatically performs the frequency

sweep for the cantilever, approaches the Z-stage to

the sample, and autofocuses the sample

allowing the user to see and navigate the area of interest for

imaging.

3 “Image”

The system sets all the necessary parameters for

optimum setting, then engages the cantilever and

starts scanning the sample. It continues to scan

until the image is acquired and completed.

End

The cantilever will disengage from the sample, and

ready for the next sample imaging.

Park SmartScan Offers

Solutions to Save You

Time

SmartScan Auto performs all the necessary

operations for imaging and intelligently decides on

the optimum image quality and scan speed, all

autonomously. SmartScan Auto is made possible by

Park’s proprietary enabling technologies. That saves

you time, money, and makes for a better end result.

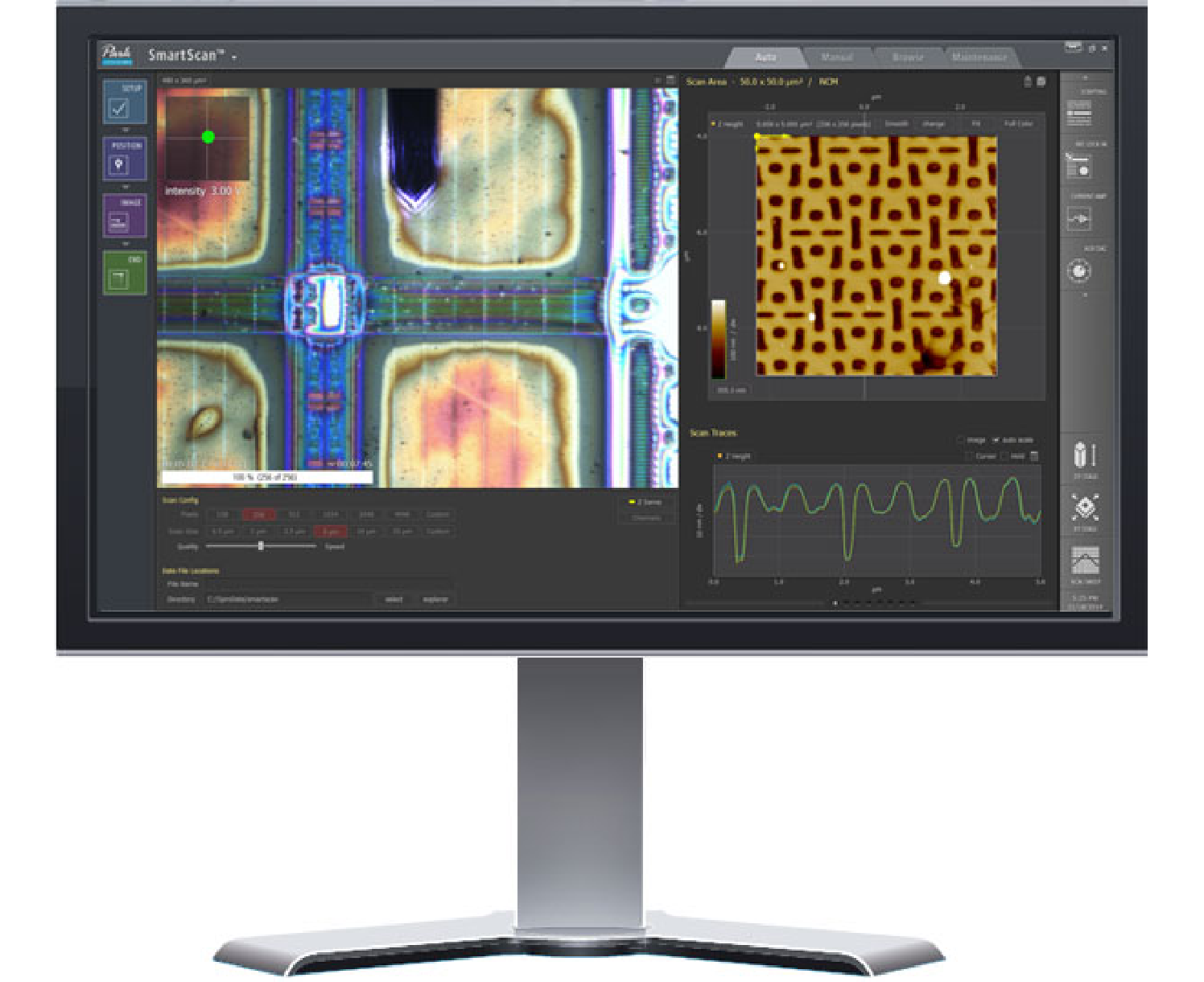

User-Friendly UX

With the SmartScan UI and layout, everything is at

your fingertips. A large optical window provides

easy access to a view of the laser reflection, the

tip, sample, laser PSPD alignment, and controls for

XY stage and Z stage movements. It also allows you

to easily control the vision, the XY stage, Z stage,

light strength, and more with the scroll of a mouse.

Command up to 8 individual trace-lines, or

channels, at once (e.g. topography, EFM,

amplitude, and scan rate) and conveniently save

custom trace-line profiles.

Users may also plot any two signal channels on the

same real-time dual-axis graph for comprehensive analysis.

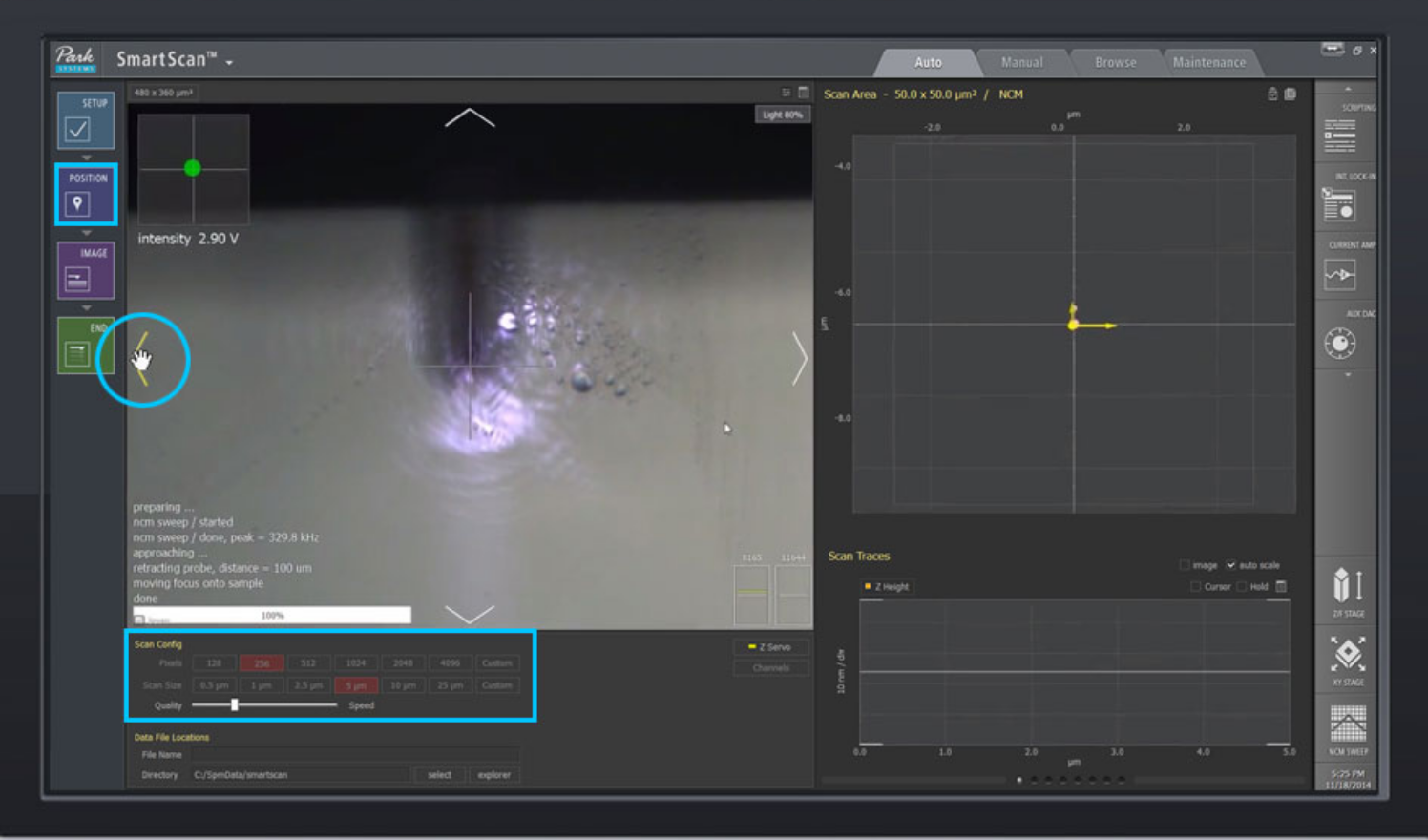

FastApproach™

At a click of a button, the Z scanner approaches

the sample automatically and at a much higher

speed than a typical manual approach. Park's

unique FastApproach™ safely takes the probe

down to the sample surface at full speed without

requiring the user's intervention and engages just

10 seconds after loading the cantilever.

Easy to Find an Area of Interest

After probe-to-surface engagement, the optical

camera will automatically focus on the sample to

find your region of interest (ROI). The UX of

SmartScan™ easily enables intuitive navigation of

the sample by controlling the motorized stages in

the integrated optical window. You can move to

the ROI directly by clicking the desired position in the

optical window.

Single-Click Imaging with

SmartScan™ Auto Mode

All you need to specify for AFM imaging are pixel

density and scan size. Outside of those factors, you

can leave all sophisticated AFM parameters up to

the Auto mode of SmartScan™. The system will

start a measurement with optimized conditions for

imaging automatically at the click of a button.

Speeds Up Imaging with AdaptiveScan™

Park's innovative AdaptiveScan™ controls the scan

speed automatically based on the peaks and

valleys of the sample surface. AdaptiveScan™

adjusts the optimum scan speed dynamically to

acquire a quality image of an unknown

morphology at a higher speed. This effectually

shortens the imaging time while retaining top

image quality comparable to that obtained by a

well-trained expert manually. When moving to

neighboring locations or zooming-in to a target,

AdaptiveScan automatically applies a new optimal condition.

Wizard Guides

A setup wizard embedded in the software easily

explains the necessary steps for each operation. It

includes schematics that are self-explanatory and

allow for quick, easy operation even for an inexperienced AFM

user.

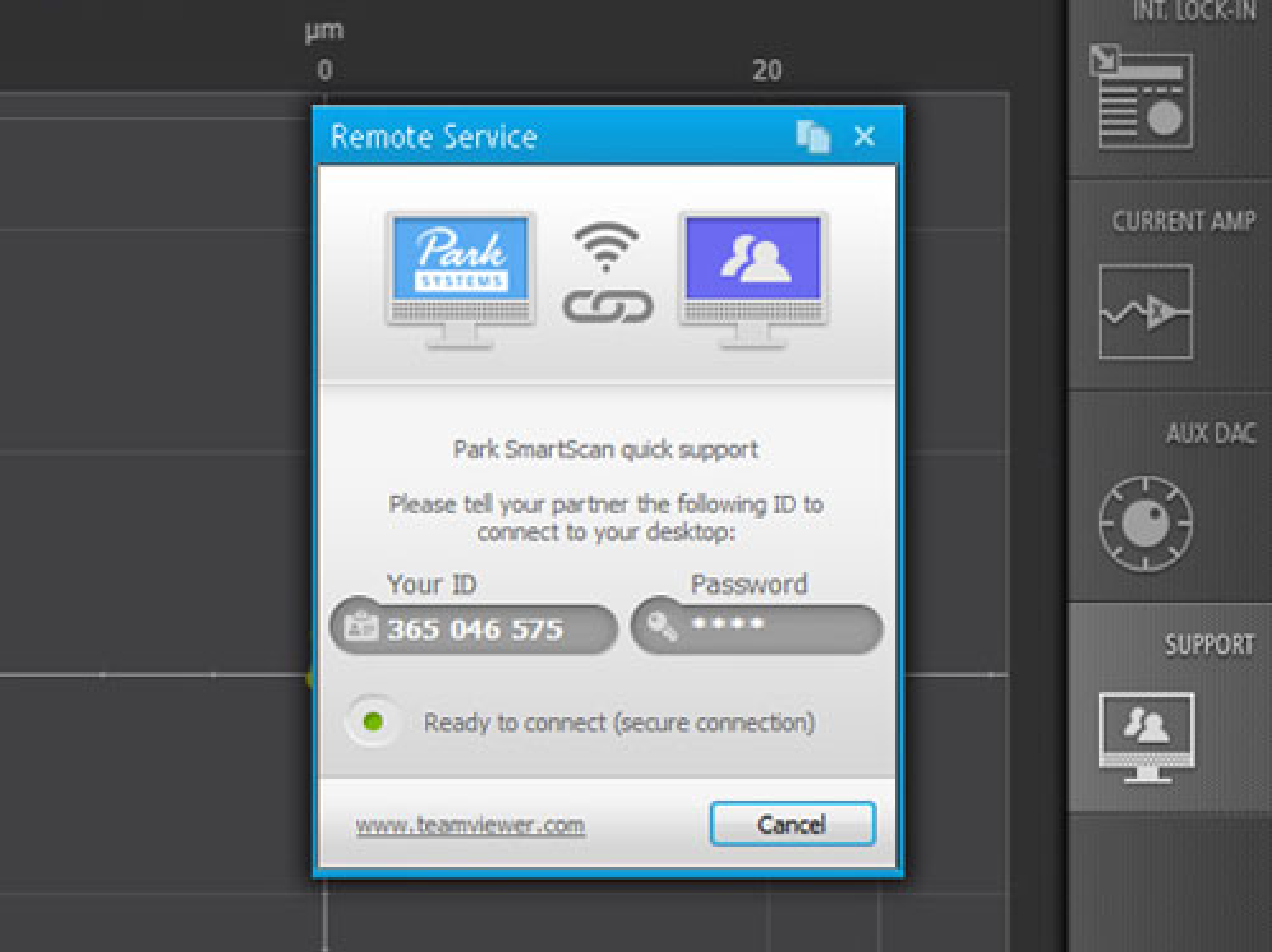

Park SmartScan Quick Support

A remote access service is integrated with

SmartScan for quick troubleshooting or assistance

with the AFM operations.

The easiest operating software available for nanolithography and nanomanipulation

Park SmartLitho, enabled by SmartScan is an AFM based platform that performs nanolithography and nanomanipulation on materials, electrical and electronics devices, nanotechnology and other areas of research.

Park SmartScan software is now available in five multiple languages, including :

Park SmartScan software is now available in five multiple languages, including :

- English

- Japanese

- Chinese

- Korean

- Russia

An AFM OS for everyone,

from amateurs to

experts

Whether your AFM needs are focused on academic

research, industrial nanometrology or failure

analysis, SmartScan™'s Auto mode offers a

streamlined system to generate publishable high- quality AFM

data. Moreover, SmartScan™ promises

productive sessions with an AFM even for

beginners or less seasoned users to obtain quality

data as good as anexpert's, without the day-and -night ordeal

of using trial and error to acquire

experience.

A Single Solution for both Auto and

Manual Operation

Although the Auto mode of SmartScan™ offers

extremely quick and easy AFM operation by

automatic optimization, SmartScan™ also provides

a way to use AFM in a typical manual mode.

In addition, powerful programmable scripting

features bring a capability to let experienced

researchers design an advanced experiment that

requires increased flexibility in data acquisition.

Better Productivity for Advanced

Experimentation : Built-in Macros

Built-in macros can be easily loaded and applied

for repeating operations, such as moving the XY or

the Z stage to a specific location, or resetting the

operation. Users can edit existing macros or create

new ones as needed.