Simply the best AFM for

automatic defect review

and surface roughness

measurement

The task of identifying nanoscale defects is a very

time consuming process for engineers working with

media and flat substrates. Park NX-HDM is an atomic

force microscopy system that speeds up the defect

review process by an order of magnitude through

automated defect identification, scanning and

analysis. Park NX-HDM links directly with a wide

range of optical inspection tools, thus significantly

increasing the automatic defect review throughput.

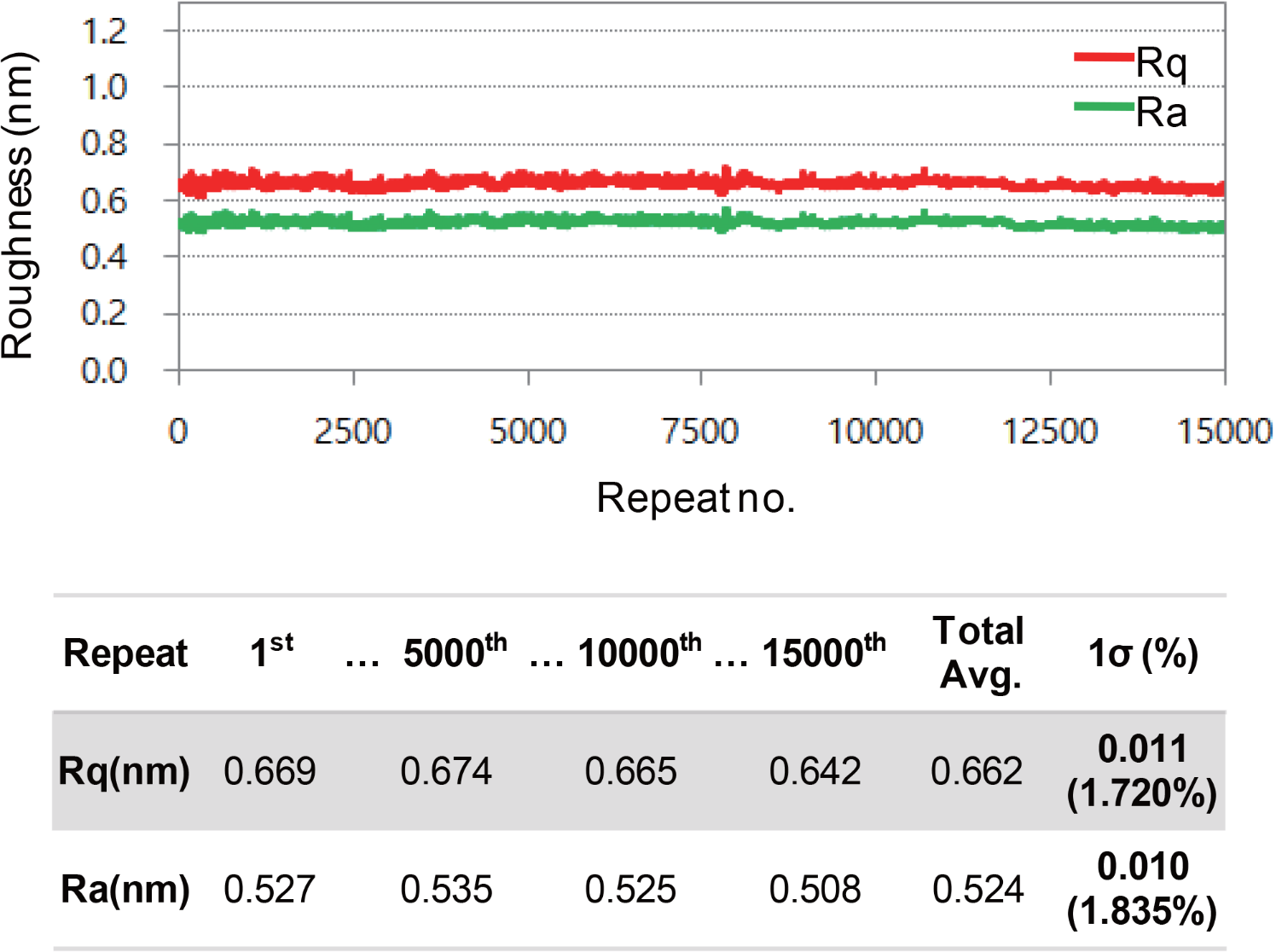

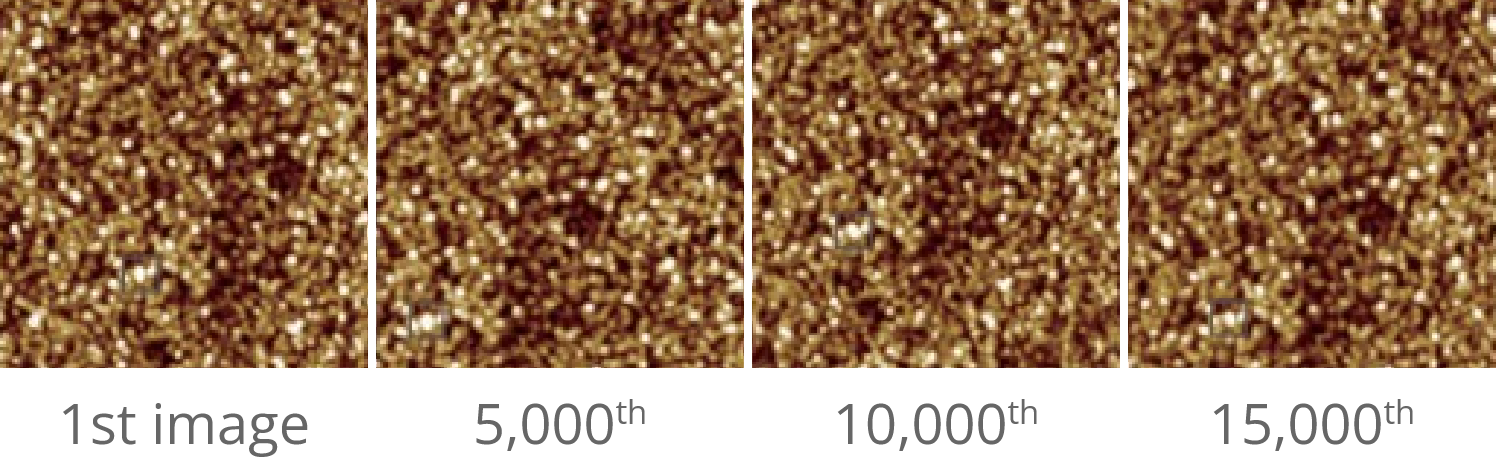

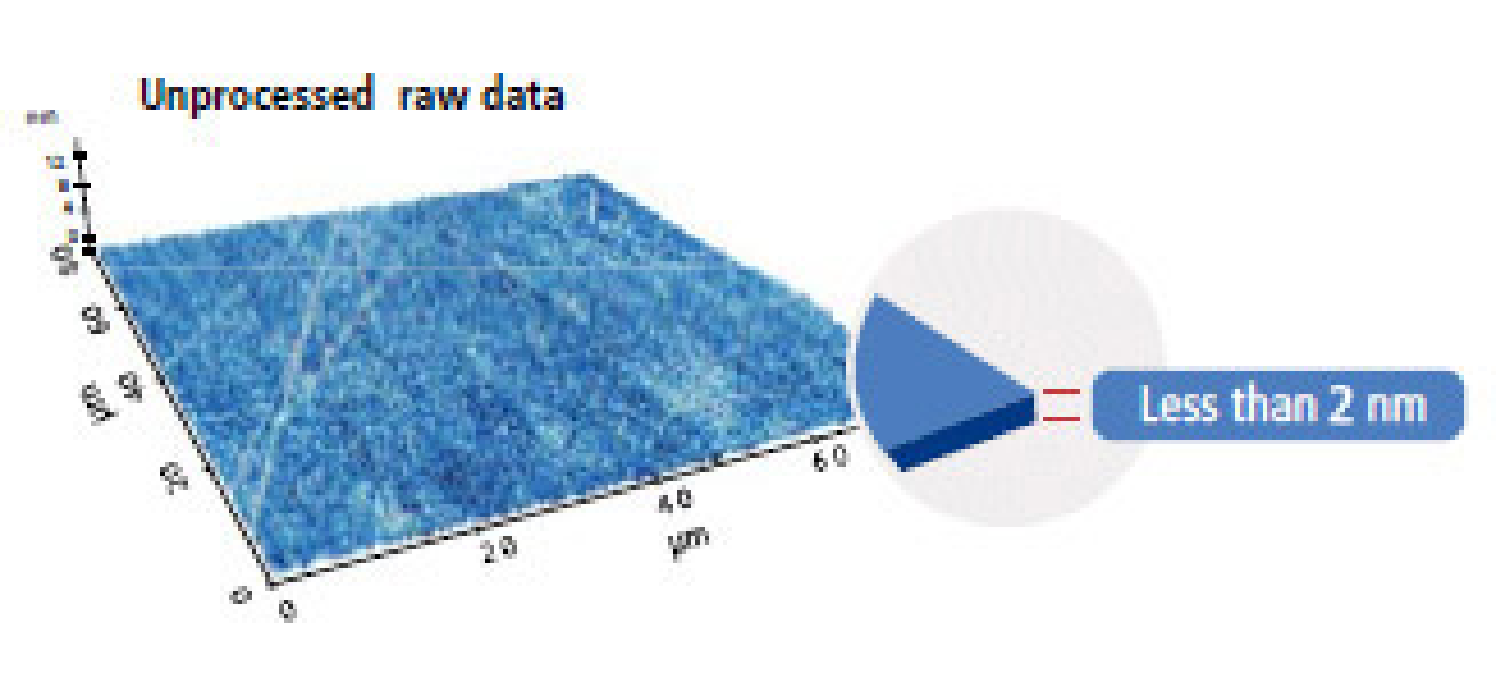

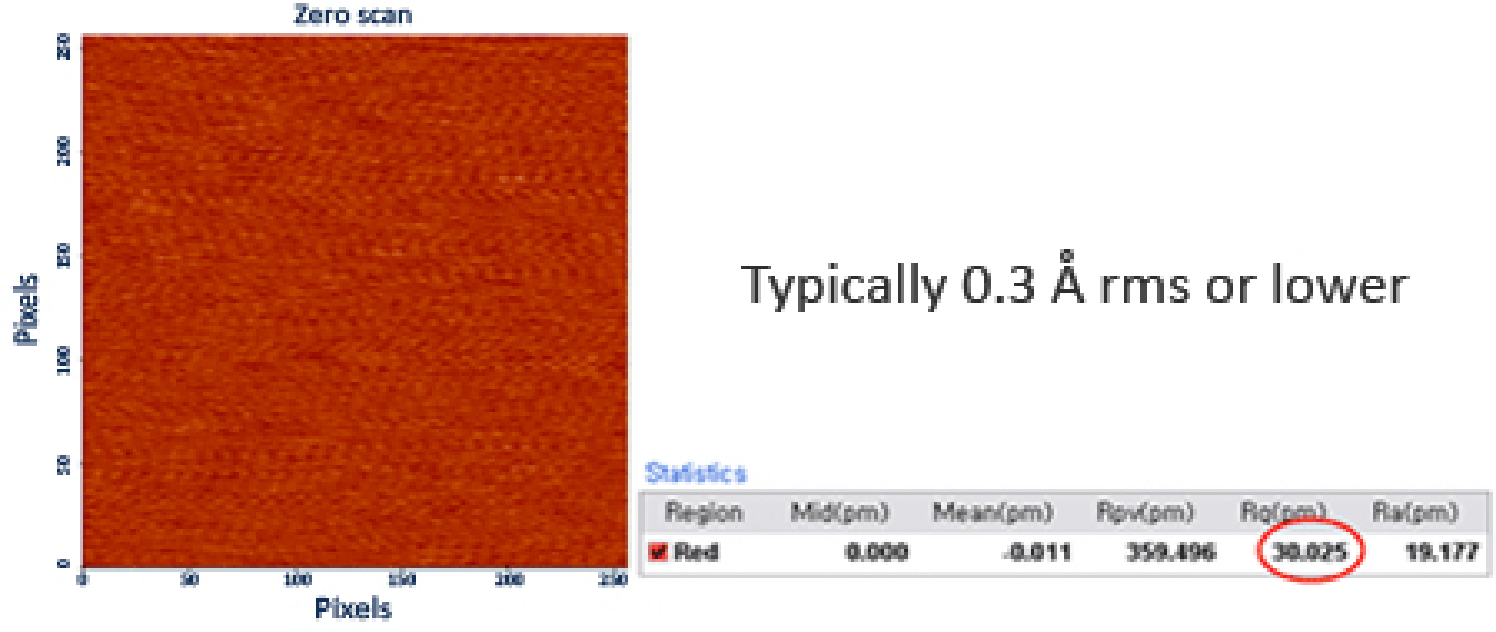

In addition, Park NX-HDM provides accurate sub-angstrom

surface roughness measurements, scan after scan.

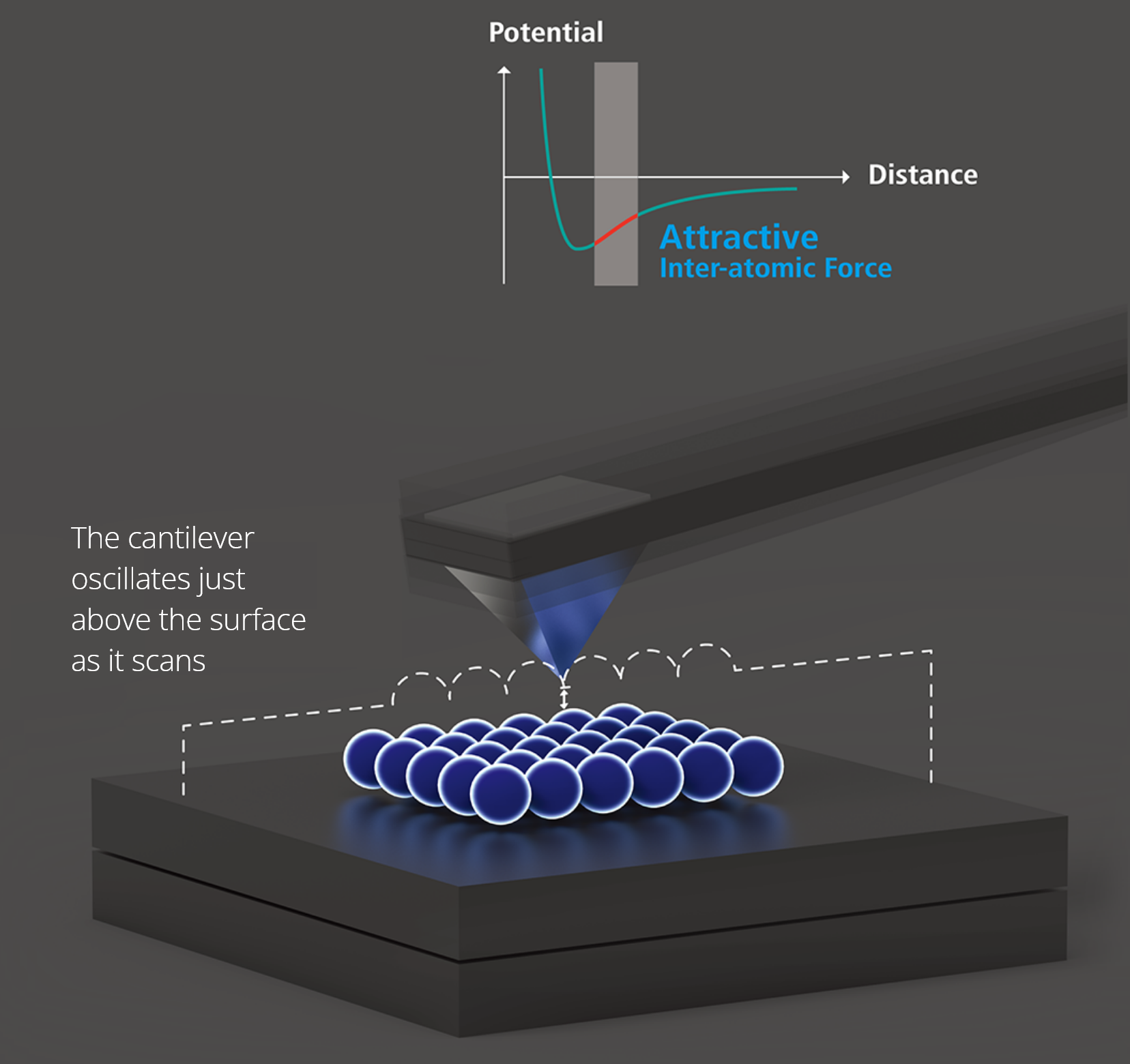

Park NX-HDM, together with its industry's

lowest noise floor, and its unique True Non-Contact™

technology, it is the most accurate AFM for surface roughness

measurement in the market.

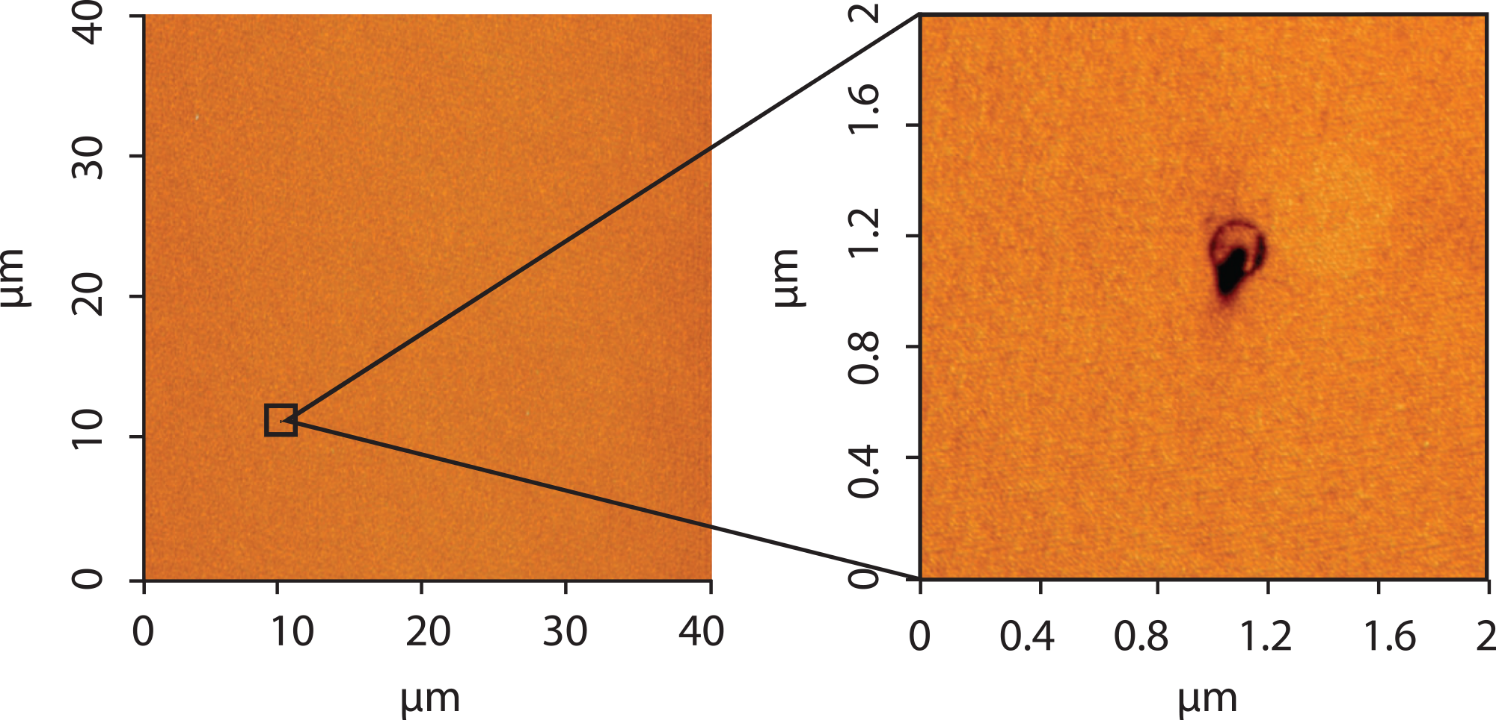

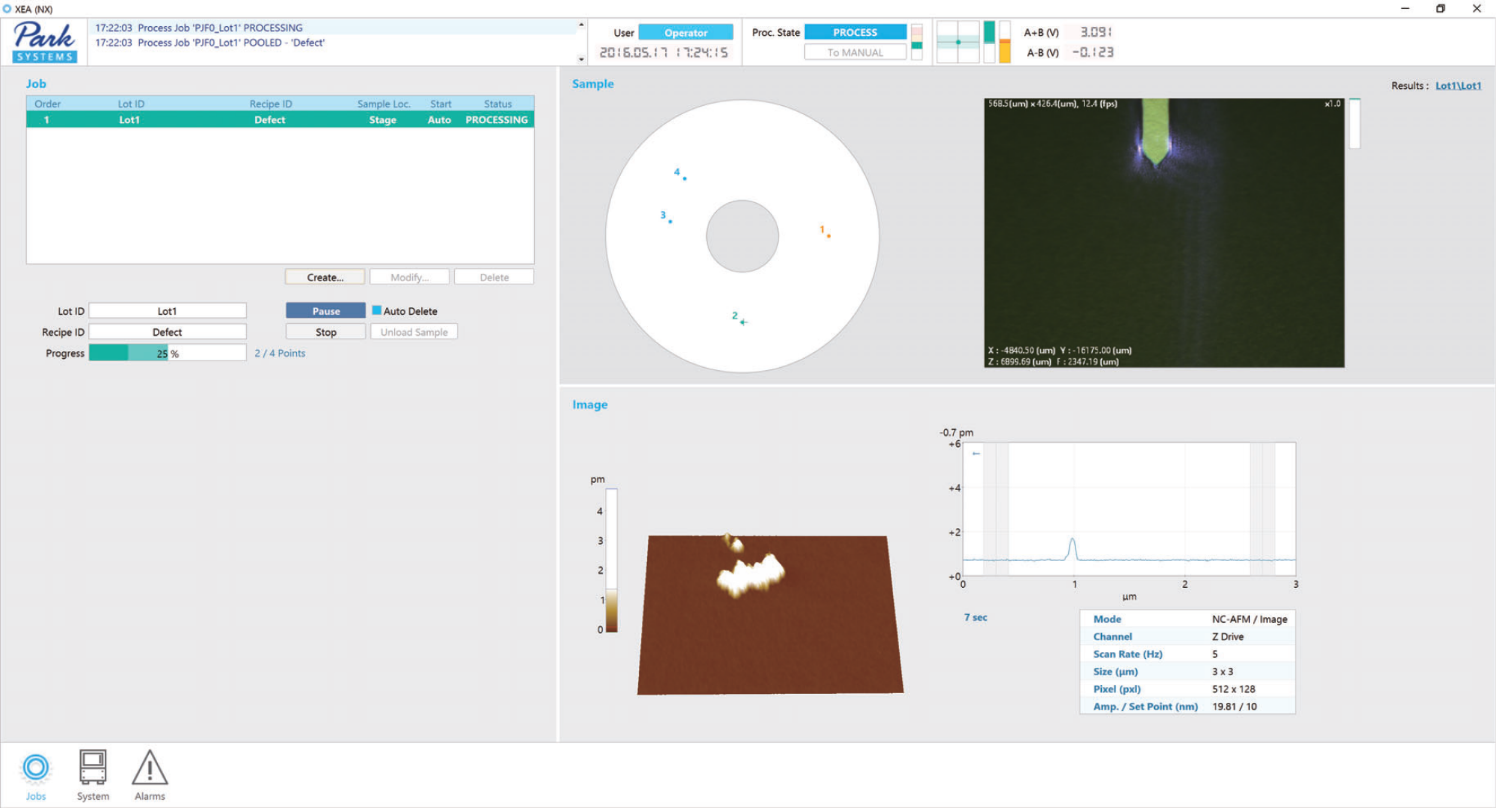

Automatic Defect Review for Media

and Substrates

- Fast defect imaging in non-contact mode

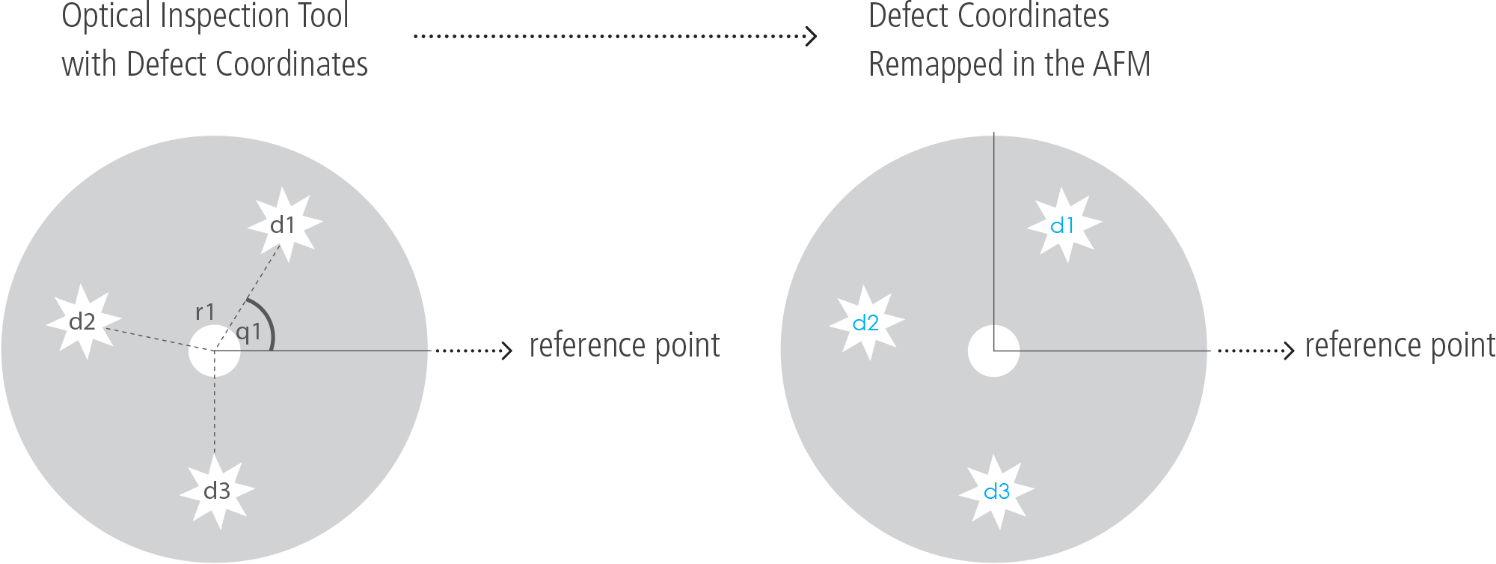

- Automated survey scan of defects mapped by optical inspection tools

- Automated zoom-in scan of specified defects

- Automated analysis of imaged defect types

- Links to a wide range of automated optical inspection (AOI) tools

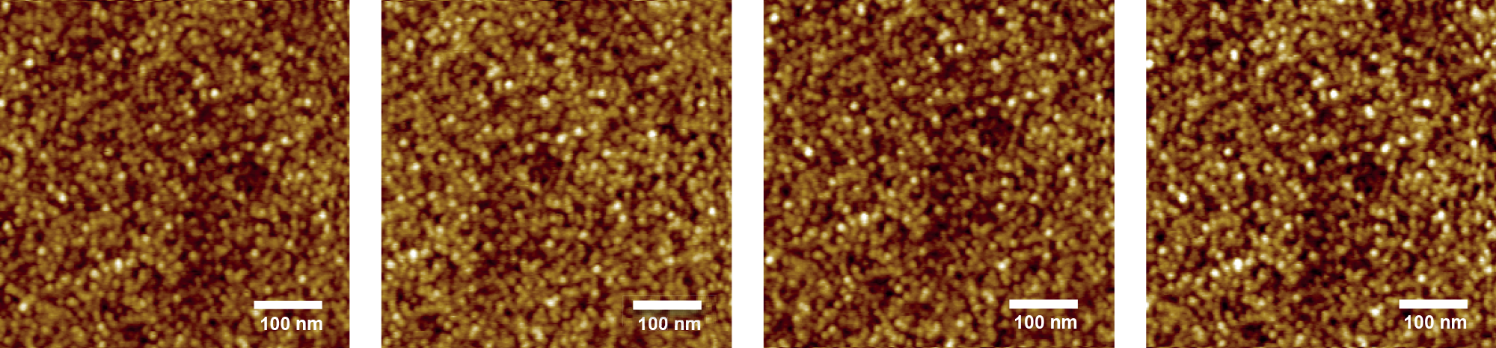

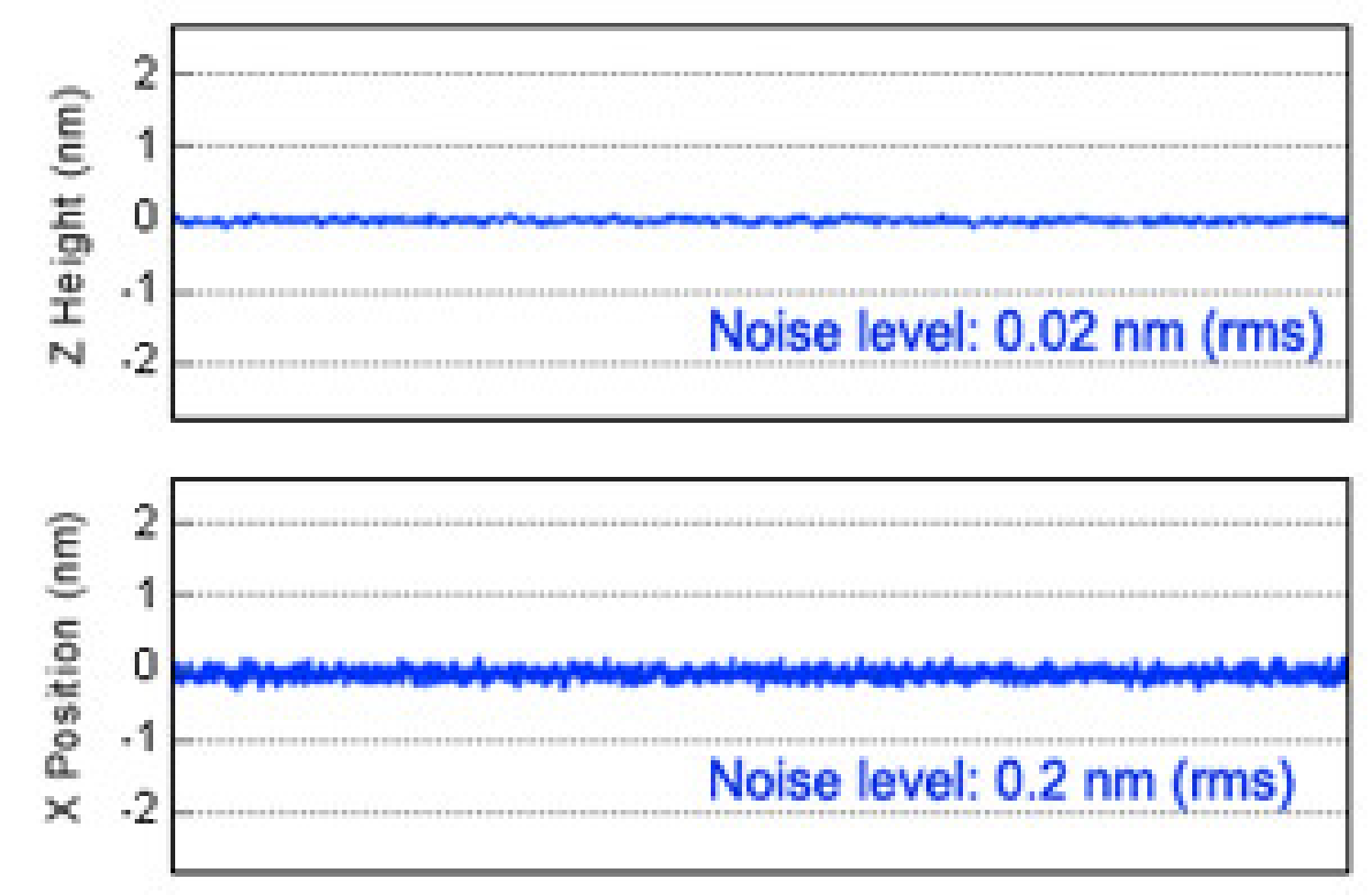

Accurate Sub-Angstrom Surface

Roughness Measurement

- Automated surface roughness measurements for media and substrates

- Industry’s lowest system noise of less than 0.5 angstrom rms

- Immunity from parameter-dependent results by True Non-Contact™ technology

- True Non-Contact™ maintains accuracy without degradation in scan resolution

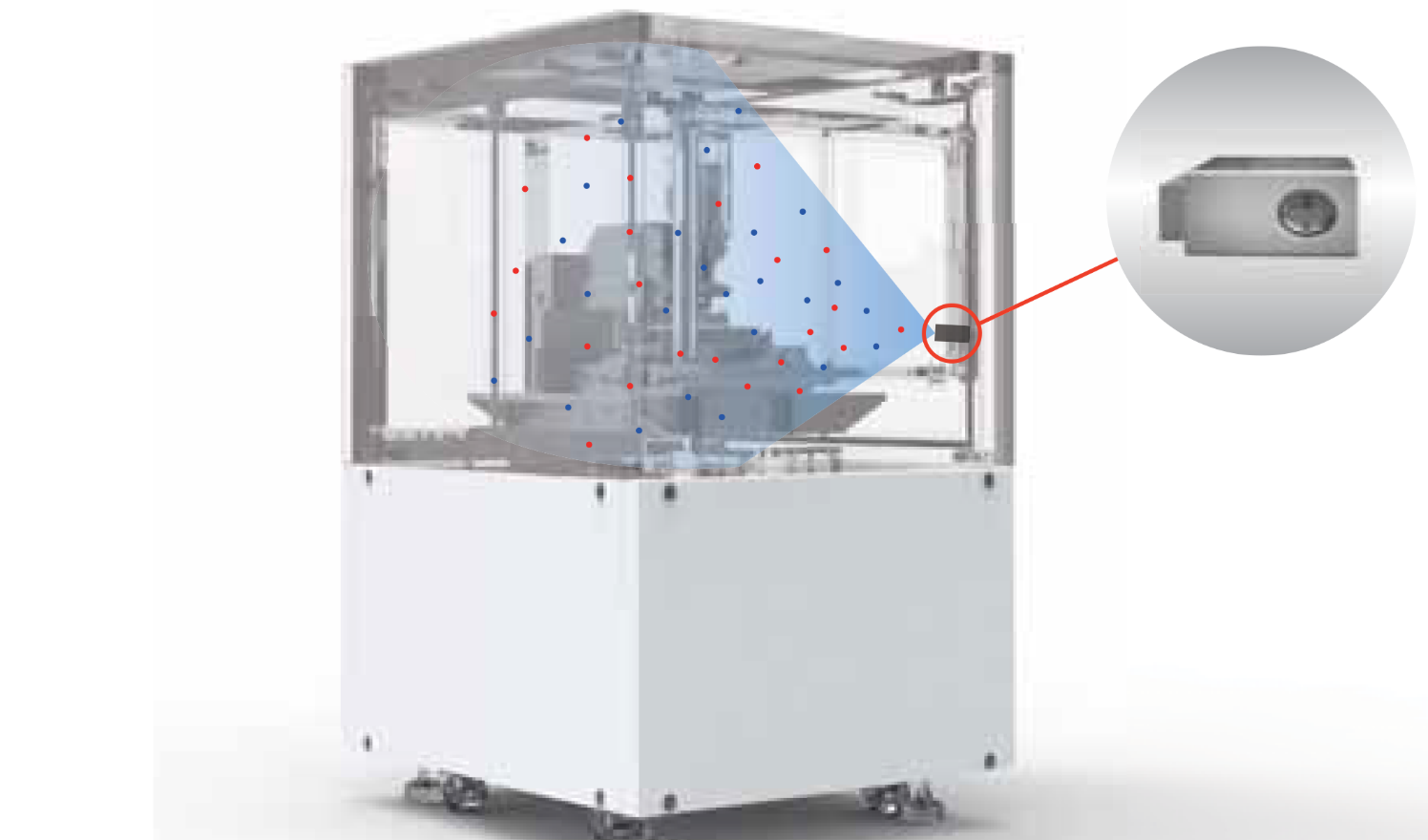

- Automatic tip exchange module (optional)

Cost Savings with True Non-Contact™

Mode

- 10 times or longer tip life during general purpose and defect imaging than any other AFMs

- Minimal tip wear from prolonged high-quality scans

- Minimized sample damage or modification

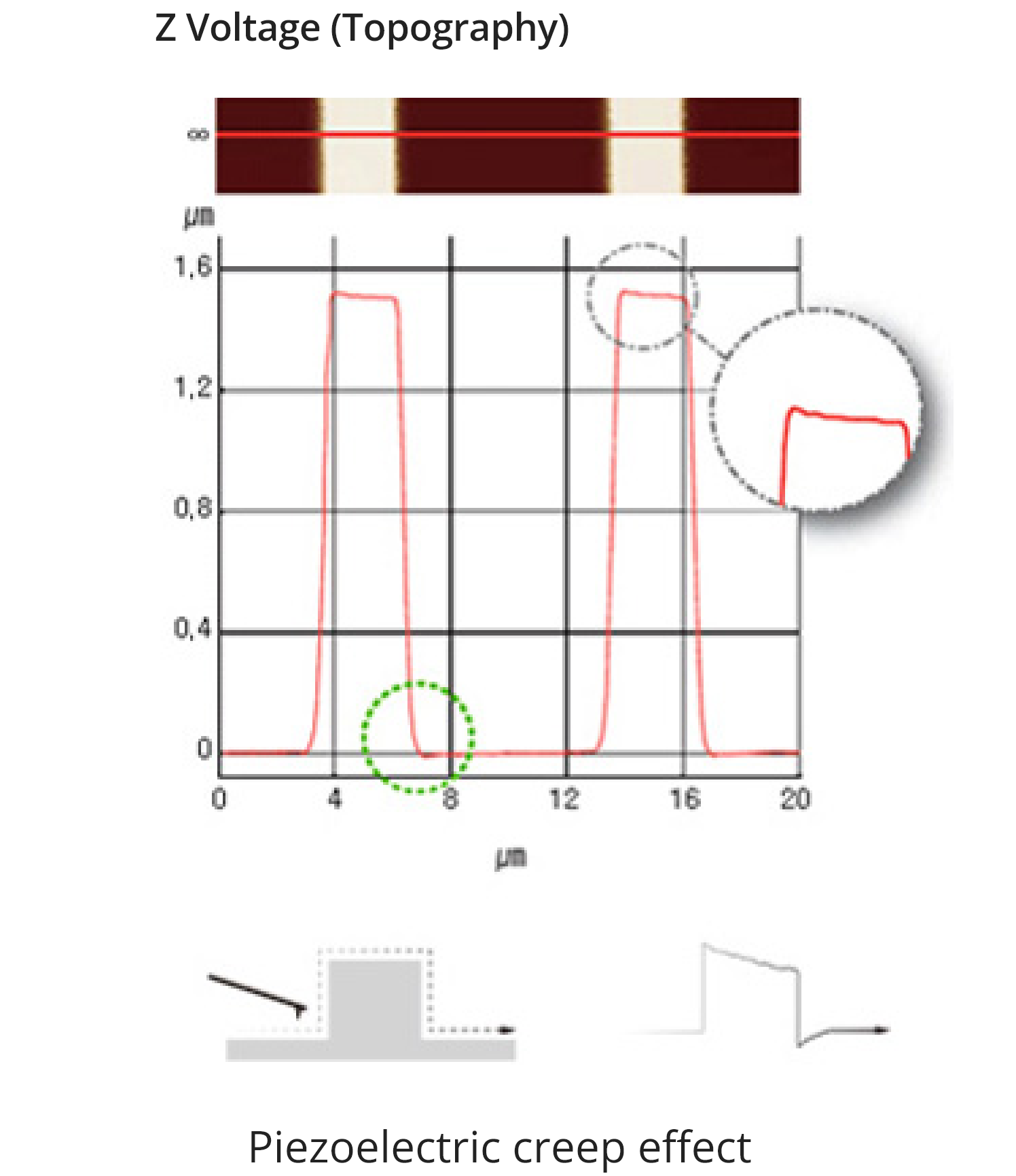

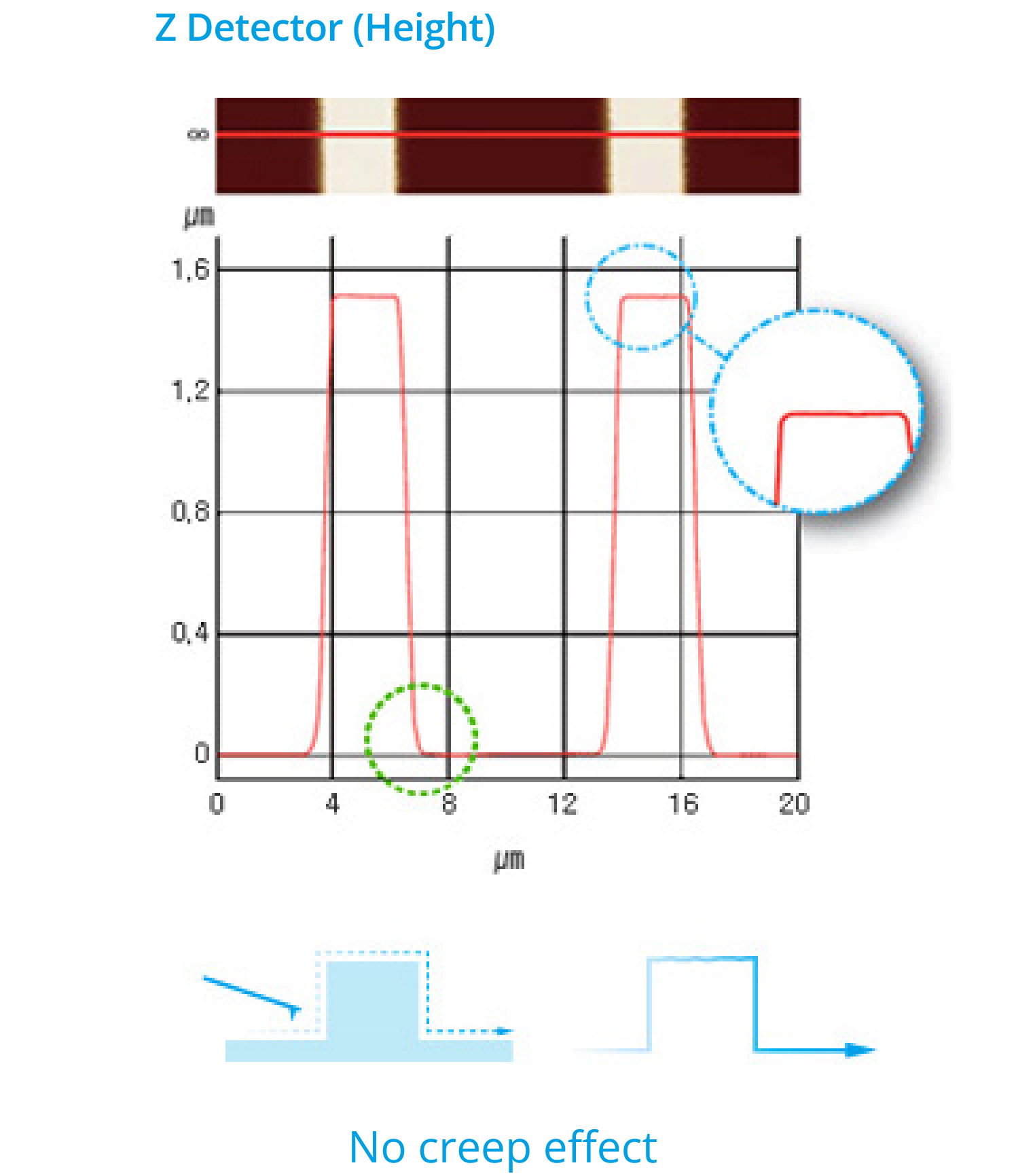

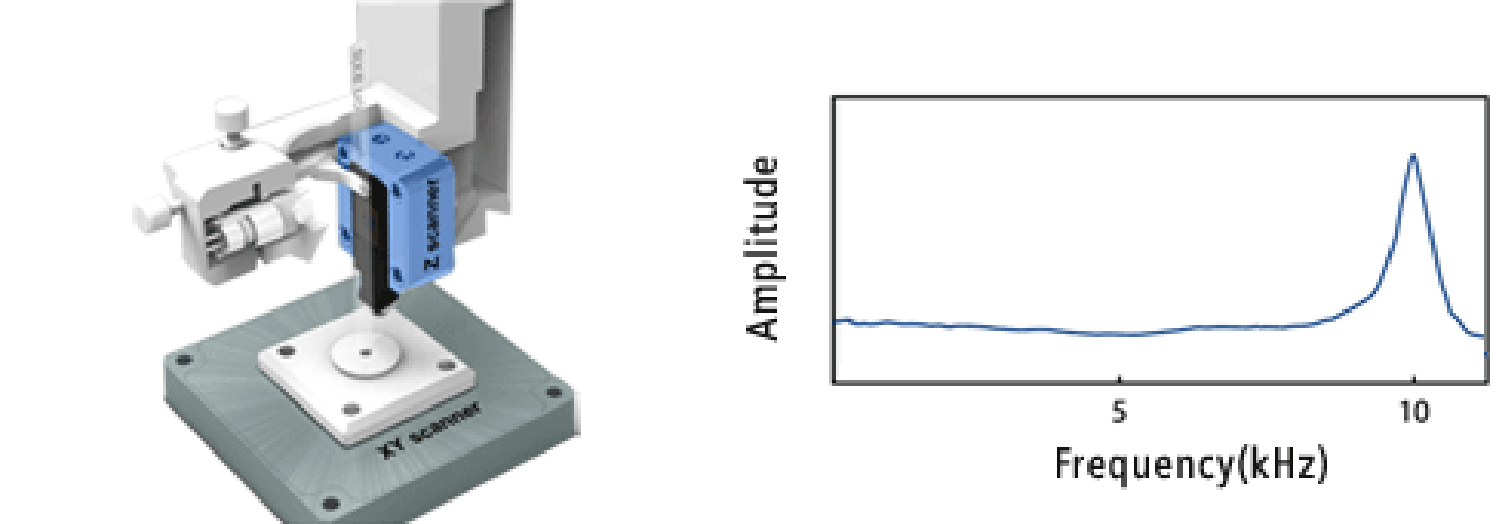

Accurate AFM Topography with Low

Noise Z Detector

- True Sample Topography™ without edge overshoot or piezo creep error

- Accurate surface height recording, even during high-speed scanning

- Industry leading forward and backward scan gap of less than 0.15%