The fully automated

industrial WLI-AFM

system

Park NX-Hybrid WLI is the first-ever AFM with built-in

WLI profilometry for semiconductor and related

manufacturing quality assurance, process control for

semiconductor front-end, back-end up to advanced

packaging, and R&D metrology. It is for those that

require high throughput measurements over a large

area that can zoom down to nanometer-scale

regions with sub-nano resolution and ultra-high

accuracy.

-

Park NX-Hybrid WLI is the first ever AFM system

with built in White Light Interferometer

profilometry for R&D metrology, process control,

and manufacturing quality assurance of semiconductor devices. -

Park NX-Hybrid WLI provides high throughput

imaging over a very large area with the WLI

module, and nanoscale metrology with

sub-angstrom height resolution over the areas of

interest using AFM. -

Park NX-Hybrid WLI offers the ultimate solution,

ranging from large area scanning to nanoscale

metrology, for various applications including

quality assurance, automatic defect review,

front-end semiconductor process control,

and back-end advanced packaging. -

Park NX-Hybrid WLI seamlessly integrates an

automated industrial AFM system and a WLI

profilometer, bringing significant cost savings,

reduced tool footprint, and new metrology

solutions compared to the previous two tool solution.

The two best

complementary

technologies for

semiconductor metrology

-

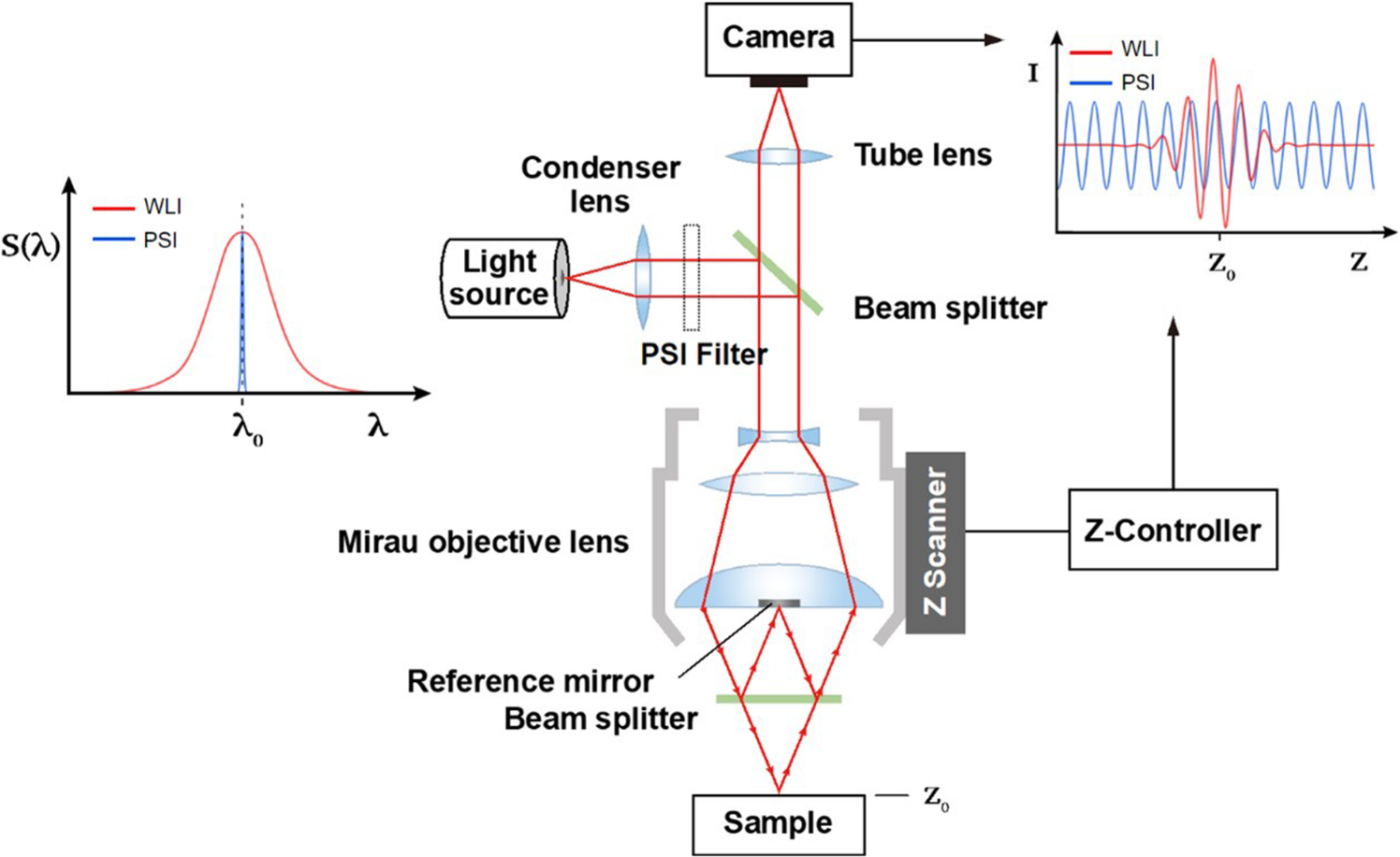

WLI : White light interferometry is an optical

technique that can image a very wide area, very

fast, producing high throughput measurements. -

AFM : Atomic force microscopy is a scanning probe

technique that delivers the highest nanoscale

resolution measurements even for transparent materials.

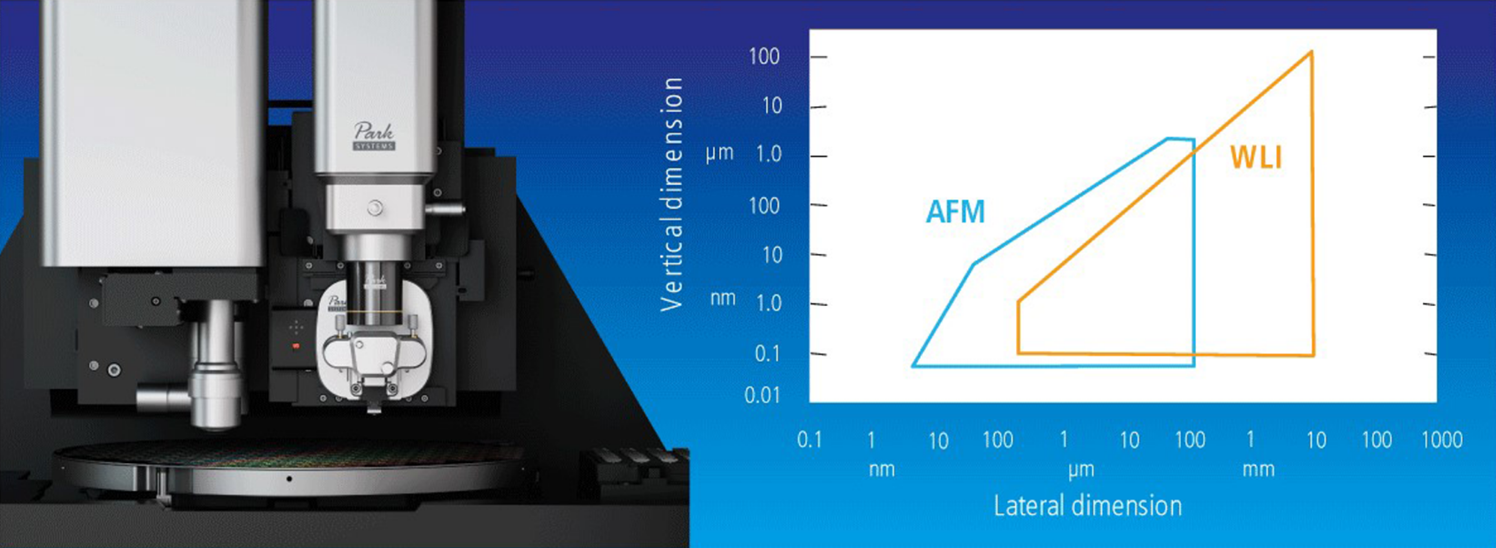

| WLI | AFM | |

|---|---|---|

| Measurement Area | Large | Small |

| Speed | High | Low |

| Lateral Resolution | Low | High |

| Vertical Resolution | High | Very High |

| Accuracy | Low | High |

WLI and AFM complement each other in field of

view, resolution, and speed

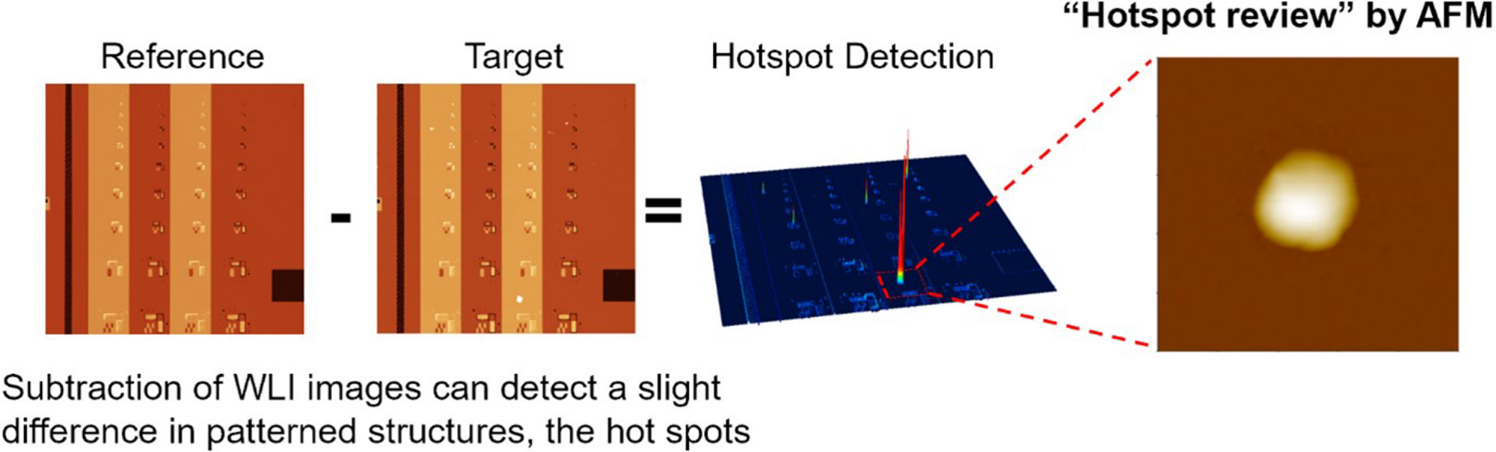

WLI applications requiring much

higher resolution and accuracy

beyond WLI capability

- WAdvanced CMP metrology and monitoring

- Advanced packaging

- Hot-spot and defect detection on full reticle die

- Wafer level metrology

AFM applications requiring much

higher throughput over much larger

areas

- In-line Wafer Metrology

- Long Range Profiling for CMP Characterization

- Sub-Angstrom Surface Roughness Control

- Wafer Inspection and Analysis