The leading nano

metrology tool for failure

analysis and large sample

research

As an FA engineer, you’re expected to deliver results.

There’s no room for error in the data provided by

your instruments. Park NX20, with its reputation as

the world’s most accurate large sample AFM, is rated

so highly in the semiconductor and hard disk

industry for its data accuracy.

More powerful failure analysis

solutions

Park NX20 is equipped with unique features that

make it easier to uncover the reasons behind

device failure and develop more creative solutions.

Its unparalleled precision provides high resolution

data that lets you focus on your work, while its

True Non-Contact™ mode scan keeps tips sharper

and longer, so you won’t have to waste as much

time and money replacing them.

Easy to use, even for entry level

engineers

Park NX20 has one of the most user friendly

designs and automated interfaces in the industry,

so you won’t have to spend as much time and

energy using the tool and supervising junior

engineers with the system.

This lets you focus your experience on solving

bigger problems and providing insightful and

timely failure analysis to your customers.

Accurate AFM Solutions

for FA and Research

Laboratories

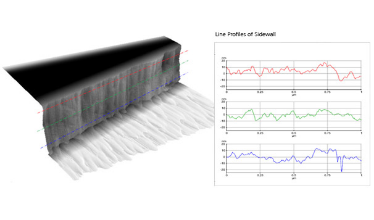

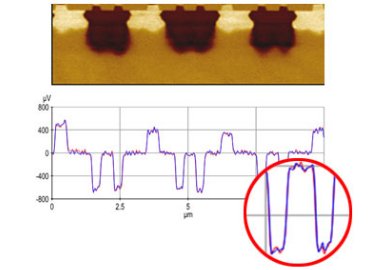

Sidewall measurements for

3D structure study

The NX20’s innovative architecture lets you detect

the sidewall and surface of the sample, and

measure their angle. This gives the unit the

versatility you need to do more innovative

research and gain deeper insights.

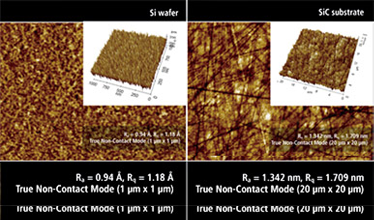

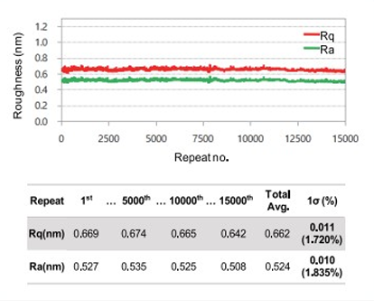

Surface roughness measurements for

media and substrates

Surface roughness is one of the key applications

where Park NX20 can excel and deliver

the accurate failure analysis and quality assurance.

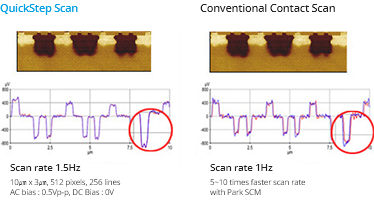

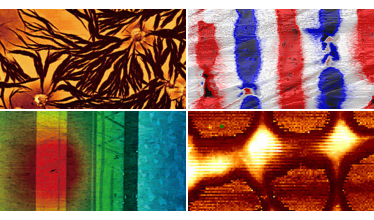

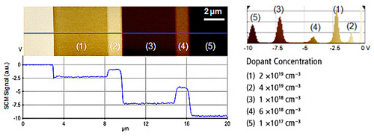

High resolution electrical scan mode

QuickStep SCM

The Fastest Scanning Capacitance Microscopy

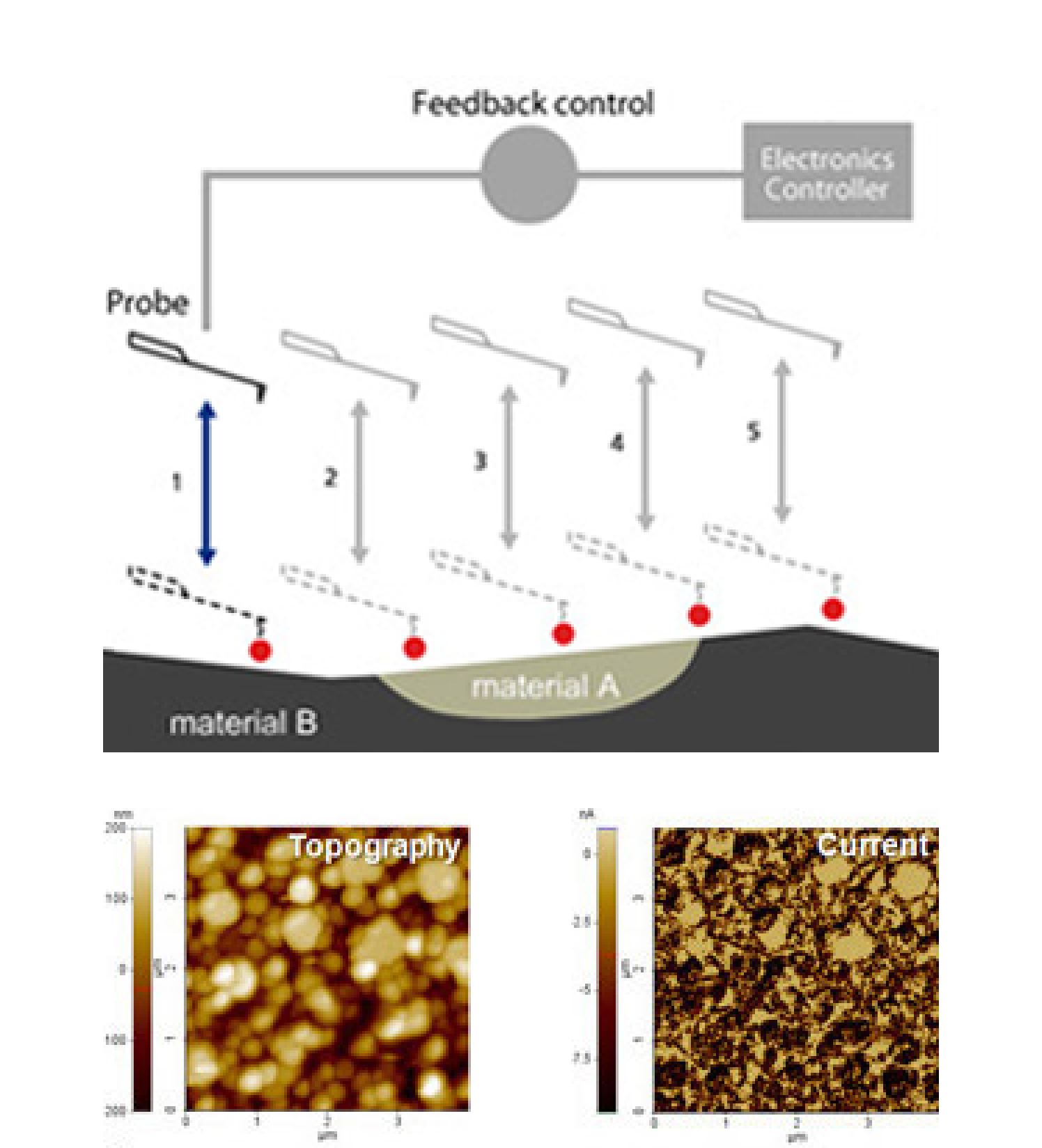

PinPoint AFM

The Frictionless Conductive AFM

Accurate AFM Scan by

True Non-Contact™ Mode

True Non-Contact™ Mode

True Non-Contact™ Mode is a scan mode unique

to Park AFM systems that produces high resolution

and accurate data by preventing destructive tip-sample

interaction during a scan.

Accurate Feedback by Faster Z-servo enables

True Non-Contact AFM

-

Less tip wear → Prolonged high-resolution scan

-

Non-destructive tip-sample interaction → Minimized sample

modification

-

Maintains non-contact scan over a wide range of samples

and conditions

Unlike in contact mode, where the tip contacts

the sample continuously during a scan, or in

tapping mode, where the tip touches the sample

periodically, a tip used in non-contact mode does

not touch the sample. Because of this, use of non-contact

mode has several key advantages.

Scanning at the highest resolution throughout

imaging is now possible as the tip’s sharpness is

maintained.

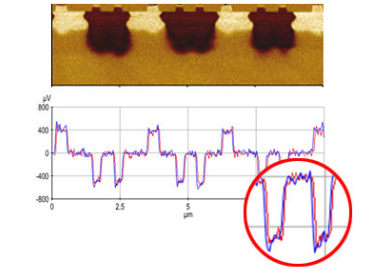

Accurate AFM

Topography with

Low Noise Z Detector

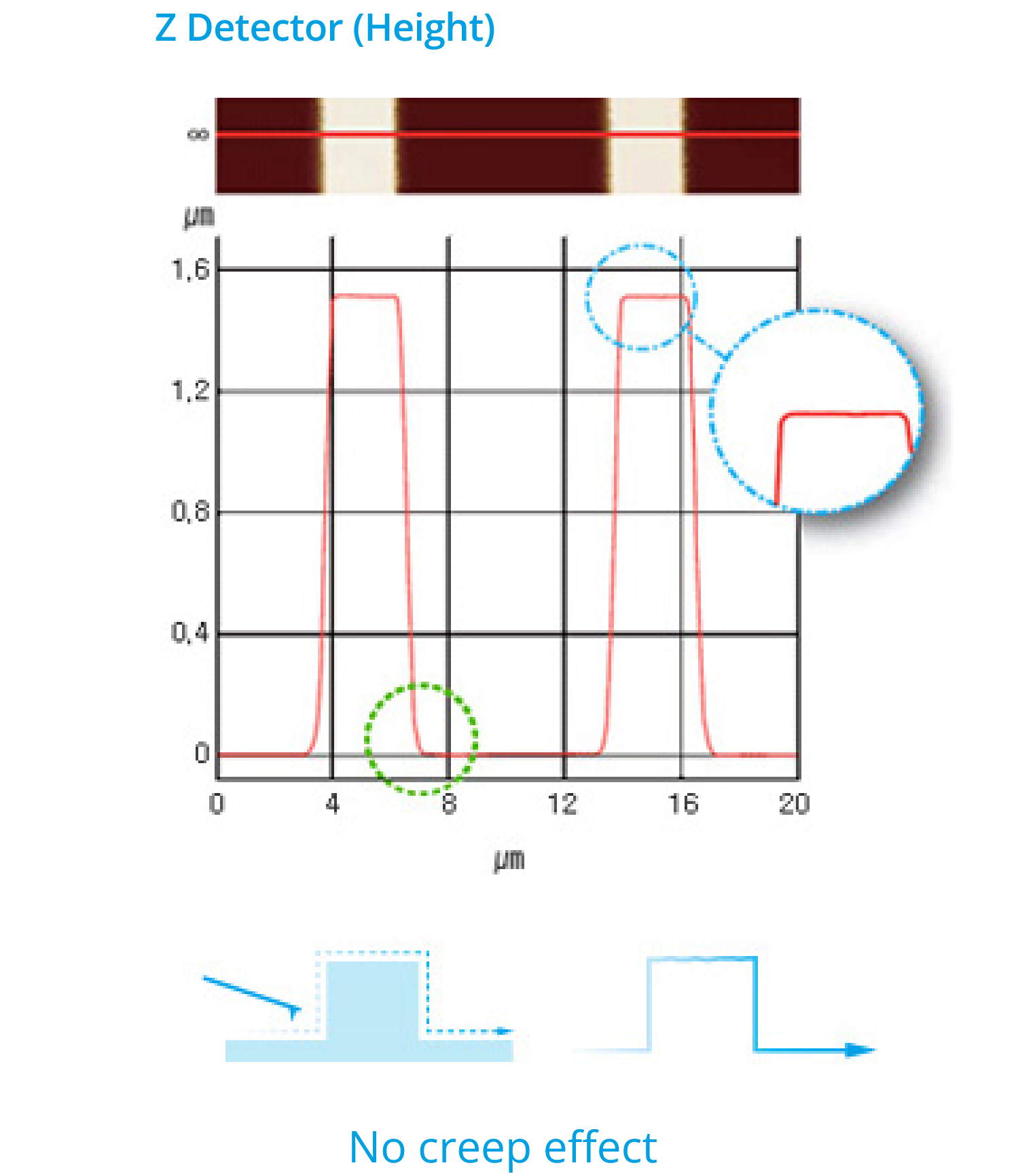

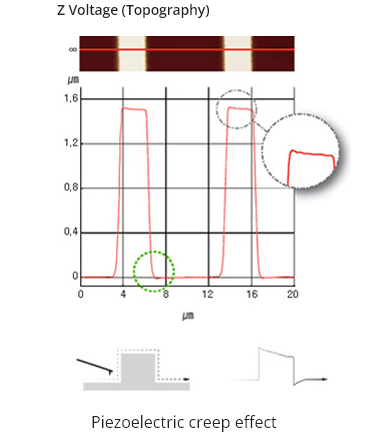

True Sample Topography™

without piezo creep error

Our AFMs are equipped with the most effective

low noise Z detectors in the field, with a noise

of .02 nm over large bandwidth.

This produces highly accurate sample topography,

no edge overshoot and no need for calibration.

Just one of the many ways Park AFM saves your

time and gives you better data.

-

Low noise Z detector signal is used for topography

-

Low Z detector noise of 0.02 nm over large bandwidth

-

No edge overshoot at the leading and trailing edges

-

Calibration needs to be done only once at the factory