The leading automated

nanometrology tool for

300 mm wafer

measurement and

analysis

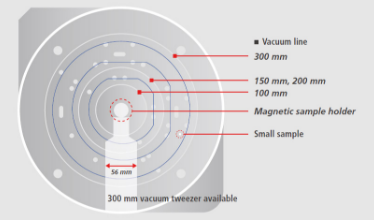

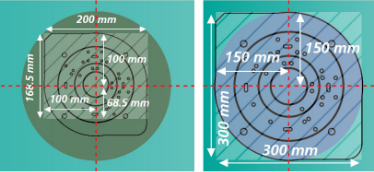

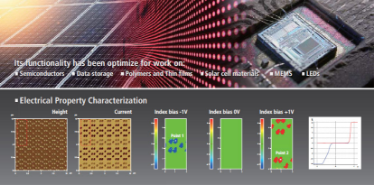

The Park NX20 300mm is the industry's first large

sample AFM that supports a full motorized traveling

range of 300 mm x 300 mm.

Designed for failure analysis and quality control

laboratories, the new upgraded Park NX20 system

can inspect an entire 300 mm wafer efficiently,

without any need for cumbersome sample

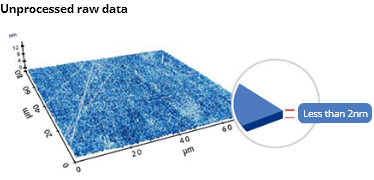

displacement. Despite the enlarged platform to

support the 300 mm motorized XY stage, Park's

innovative vibration isolation technology keeps the

system noise level below 0.5 angstrom (Å) RMS or

typically 0.3 Å RMS in the field.

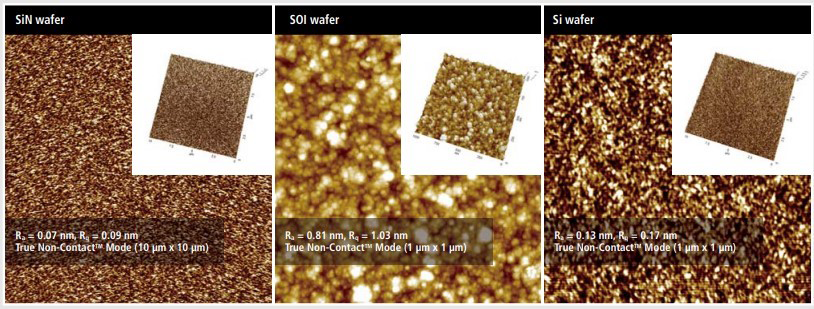

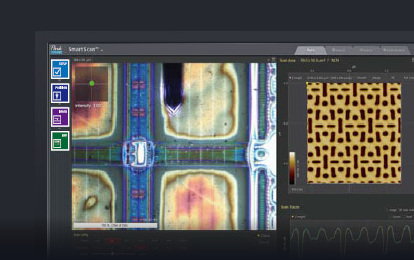

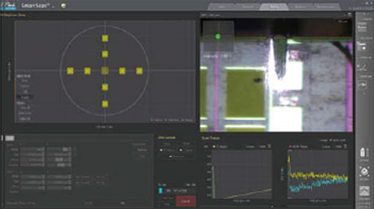

Proven AFM performance and SingleClick-AFM

automation eliminates any need for sample

adjustment and makes of Park NX20 the scanning

process as efficient and user-friendly as possible.

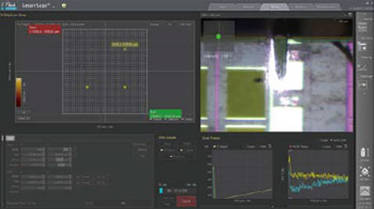

With our "Program Mode" interface users can easily

implement reliable and repeatable sequential

multiple-site measurements over the entire 300mm

x 300mm area. This makes the NX20 300 mm the

premiere choice for FA, QA, and QC engineers that

need to scan large samples.