Increase your

productivity with our

powerfully versatile

atomic force microscope

The Park XE15 includes many unique capabilities that

make it ideal for shared labs that handle a diverse

range of samples, researchers doing multi variant

experiments, and failure analysis engineers working

on wafers. Its reasonable price and robust feature

set also make it one of the best value large-sample

AFMs in the industry.

The Most Convenient Sample

Measurements with MultiSample

Scan

-

Automated imaging of multiple samples in one pass

-

Specially designed multi-sample chuck for the loading of up

to 16 individual samples

-

Fully motorized XY sample stage travels up to 150 mm x 150

mm

Accurate XY Scan by Crosstalk

Elimination

-

Two independent, closed-loop XY and Z flexure scanners

-

Flat and orthogonal XY scan with low residual bow

-

Accurate height measurements without any need for software

processing

Best Tip Life, Resolution and Sample

Preservation by True Non-Contact™

Mode

-

Fast Z-servo speed enabling True Non-Contact™ Mode

-

Minimum tip wear for prolonged high-quality and

high-resolution imaging

Versatile Range of Modes and Options

-

Comprehensive set of measurement modes and characterizations

-

Expanded capabilities with optional accessories and upgrades

-

Advanced electrical measurements for failure analysis (FA)

The most convenient

sample measurements

with MultiSample™ scan

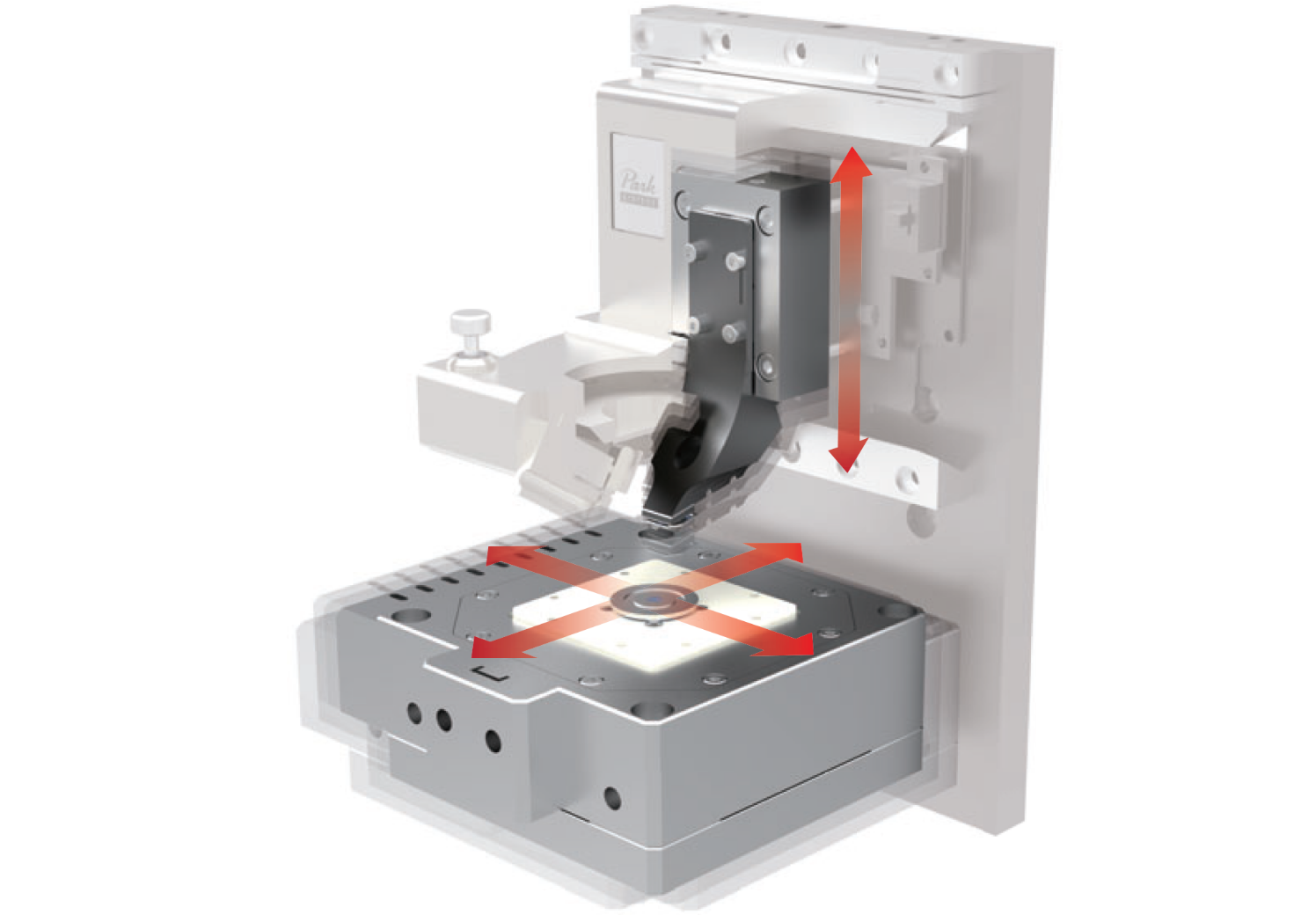

Park XE15 MultiSample™

scan system

-

Automated imaging of multiple samples in one pass

-

Specially designed multi-sample chuck for the loading of up

to 16 individual samples

-

Fully motorized XY sample stage travels up to 150 mm x 150

mm

Using the motorized sample stage, MultiSample Scan™ enables

programmable multiple region imaging in step-and-scan

automation.

Here’s how it works :

-

Register multiple scan positions defined by a

user

-

Image from the first scan position

-

Lift a cantilever

-

Move the motorized stage to the next user defined coordinate

-

Approach

-

Repeat scan

The registration of multiple scan positions is easily

carried out by either entering sample-stage

coordinates or sample de-skewing by two

reference points. This automated feature greatly

increases productivity by reducing the need for

your interaction during the scan process.

Flat Orthogonal XY

Scanning without

Scanner Bow

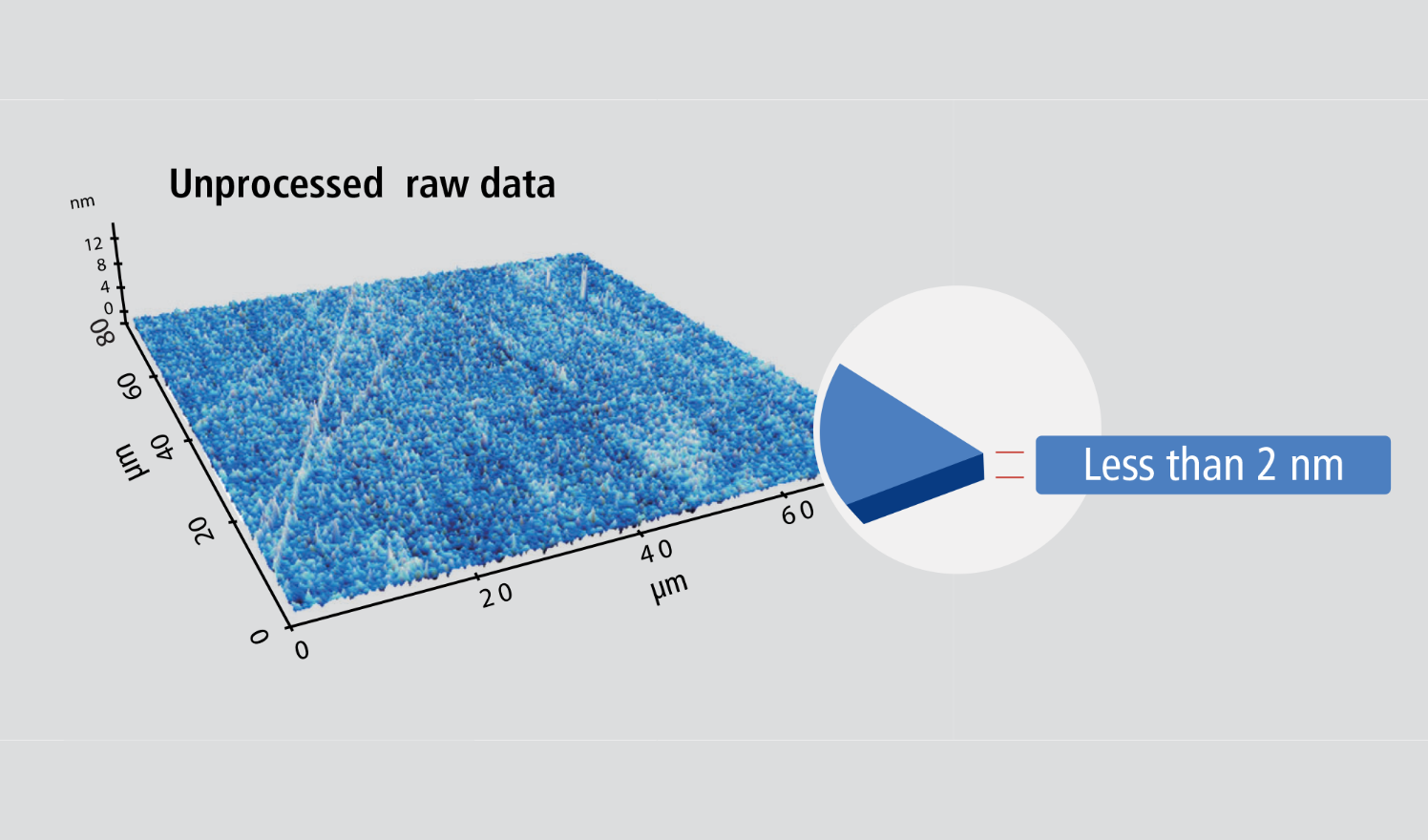

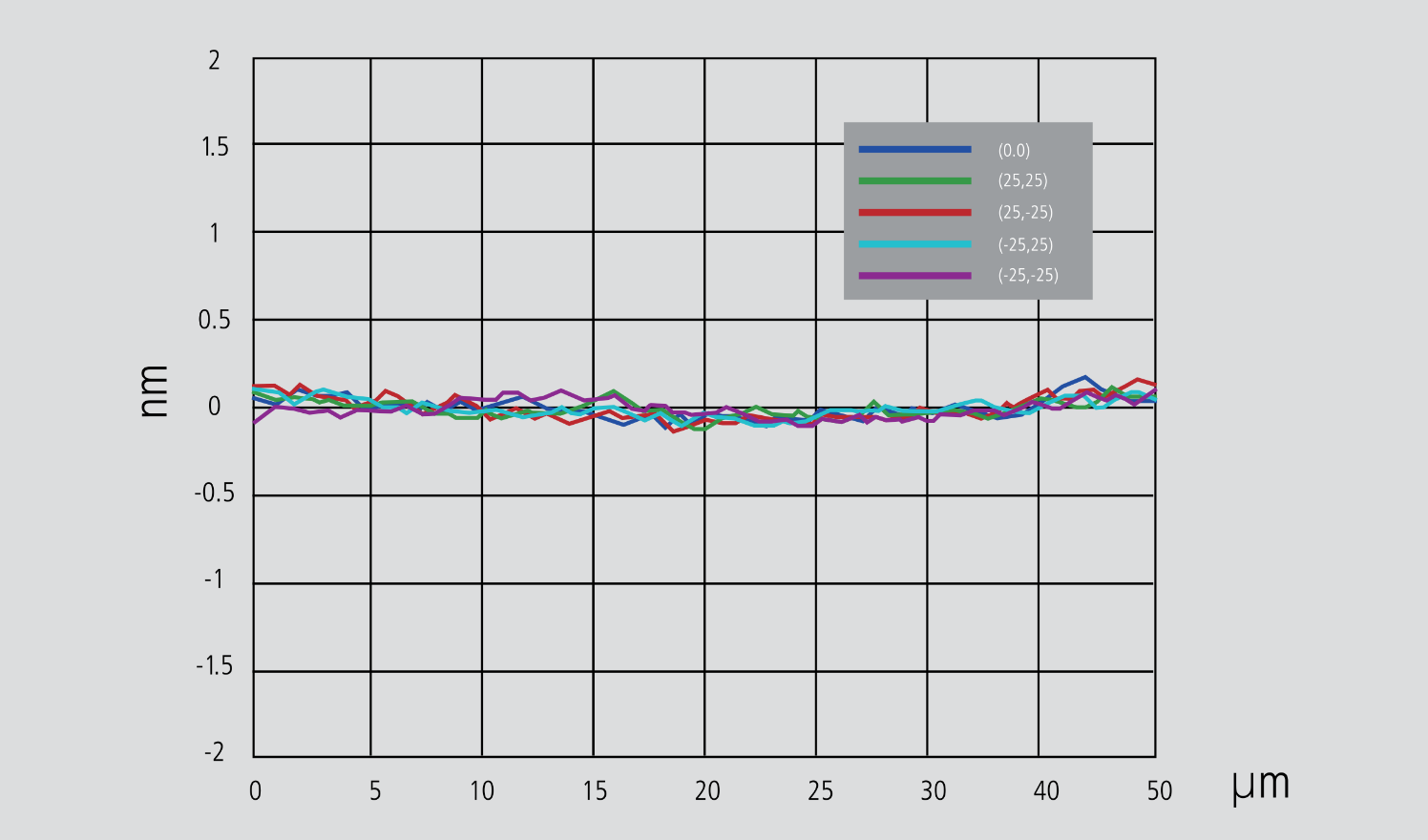

Park's Crosstalk Elimination scanner structure

removes scanner bow, allowing flat orthogonal XY

scanning regardless of scan location, scan rate, and

scan size. It shows no background curvature even on

flattest samples, such as an optical flat, and with

various scan offsets. This provides you with a very

accurate height measurement and precision

nanometrology for the most challenging problems in research

and engineering.

Decoupled XY and Z Scanners

The fundamental difference between Park and its

closest competitor is in the scanner architecture.

Park’s unique flexure based independent XY

scanner and Z scanner design allows unmatched

data accuracy in nano resolution in the industry.

Accurate Surface Measurement

"Flat" sample surface as it is!

-

Low residual bow

-

No need for software processing

-

Accurate results independent of scan location

Better tip life,

sample preservation,

and accuracy with

True Non-Contact™ Mode

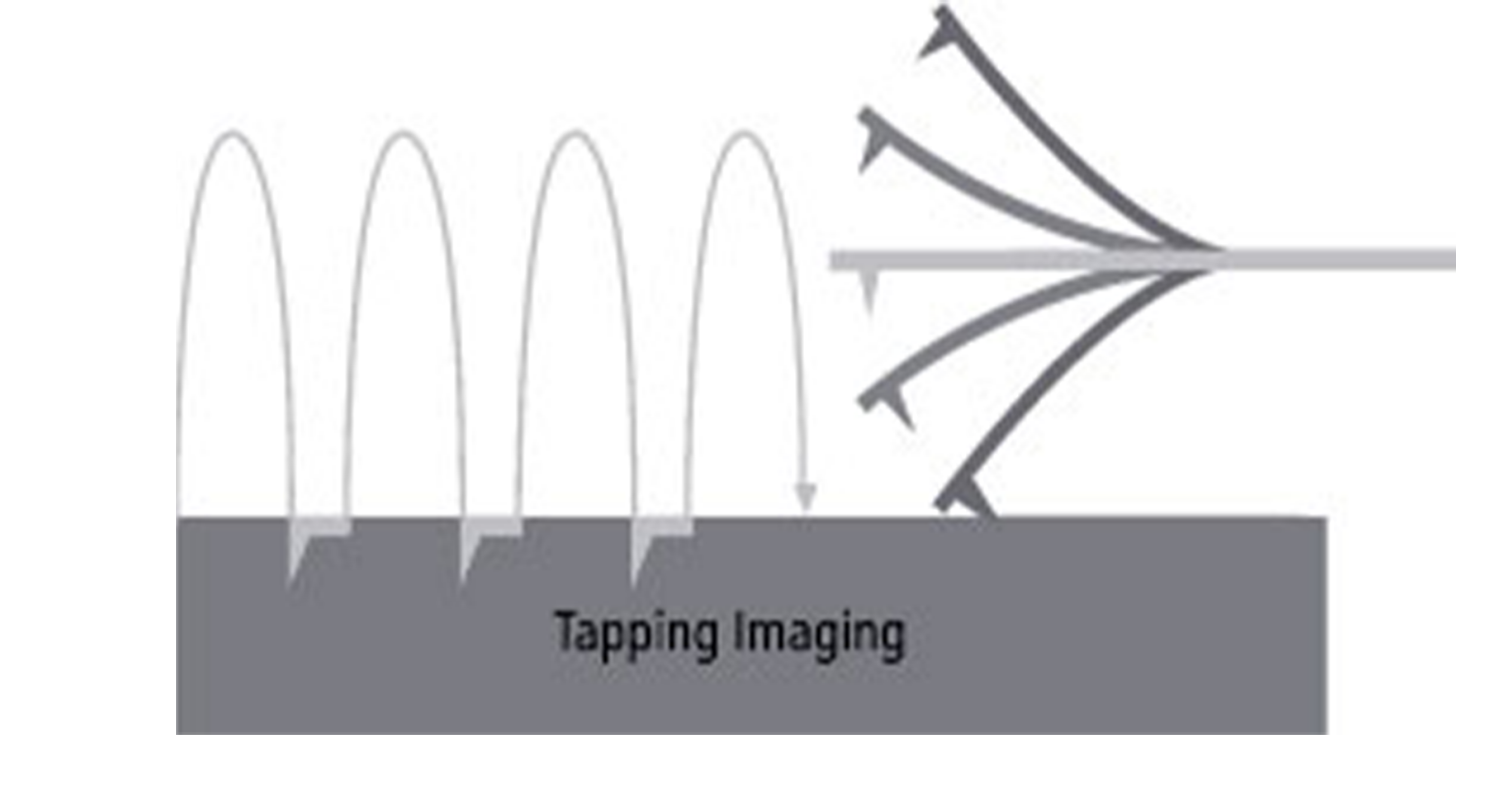

In True Non-Contact™ Mode, the tip-sample distance is

successfully maintained at a few nanometers in the net

attractive regime of inter-atomic force. The small amplitude

of tip oscillation minimizes the tip-sample interaction,

resulting in superb tip preservation and negligible sample

modification.

-

Less tip wear = Prolonged high-resolution scan

-

Non-destructive tip-sample interaction =

Minimized sample modification

-

Immunity from parameter dependent results

-

Quick tip wear = Blurred low-resolution scan

-

Destructive tip-sample interaction = Sample damage

and modification

-

Highly parameter-dependent

Longer Tip Life and Less Sample

Damage

The sharp end of an AFM tip is so brittle that once

it touches a sample, it becomes instantly blunt and

limits the resolution of an AFM and reduces the

quality of the image. For softer samples, the tip will

damage the sample and also result in inaccuracies

of sample height measurements. Consequently,

preserving tip integrity enables consistent high

resolution and accurate data.

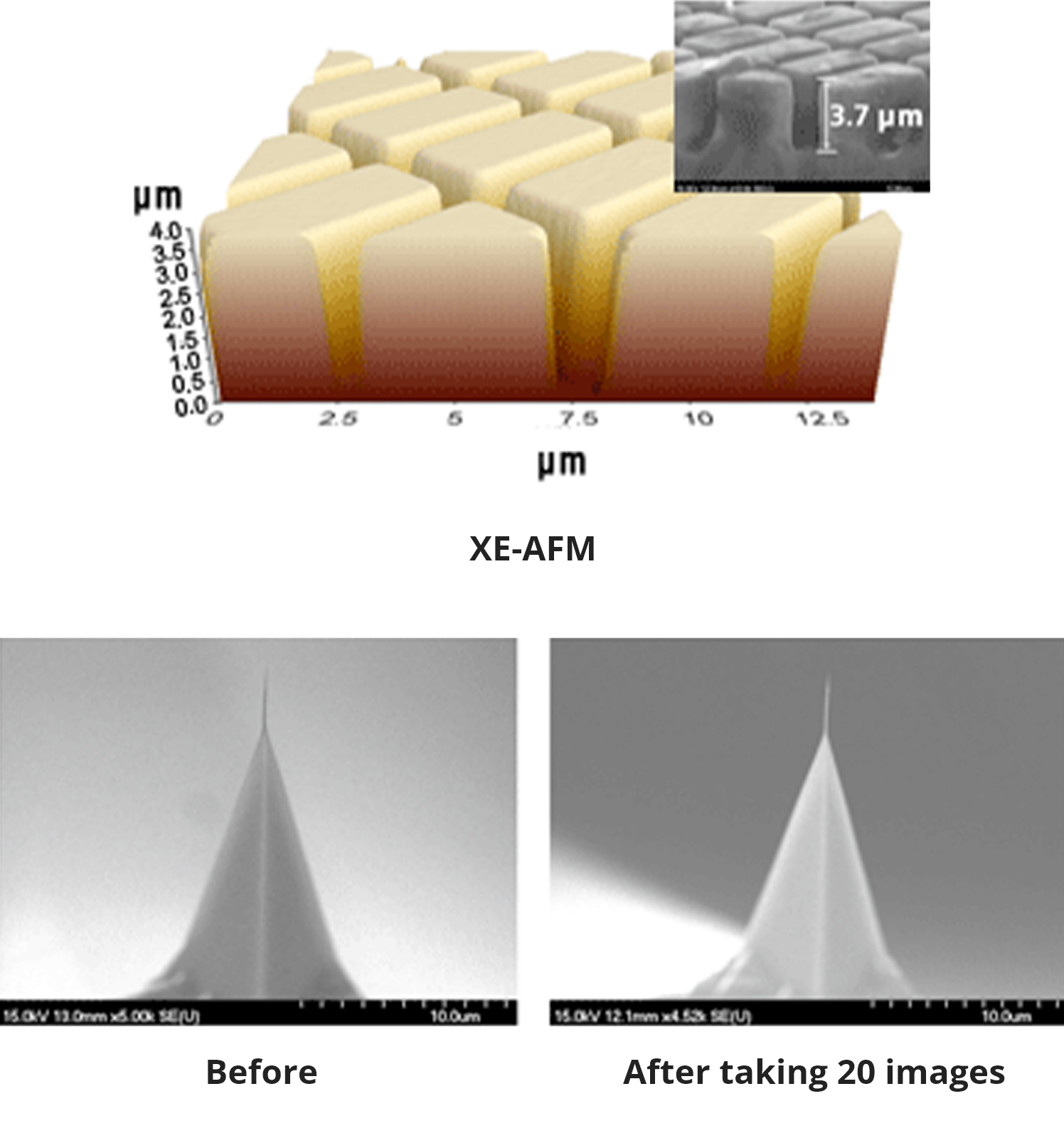

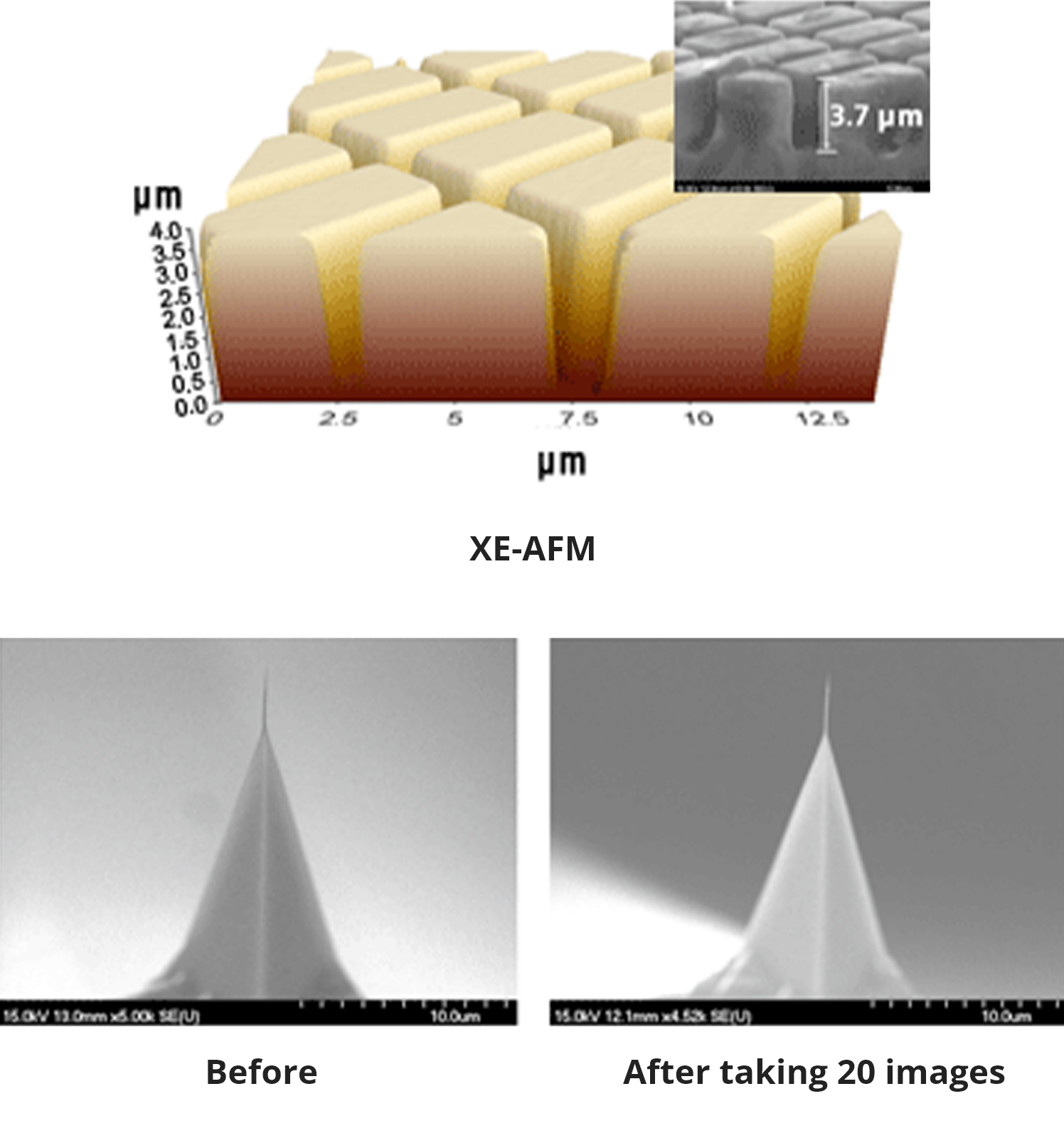

True Non-Contact™ Mode of the XE-AFM superbly

preserves the tip, resulting in a much longer tip life

and less sample damage. The figure, displayed in

1:1 aspect ratio, shows the unprocessed raw data

image of a shallow trench isolation sample imaged

by the XE-AFM, whose depth is also confirmed by

scanning electron microscope (SEM). The same tip

used in the imaging of the sample shows no tip wear even

after taking 20 images.