Powerful features for

high throughput inline

PTR measurements

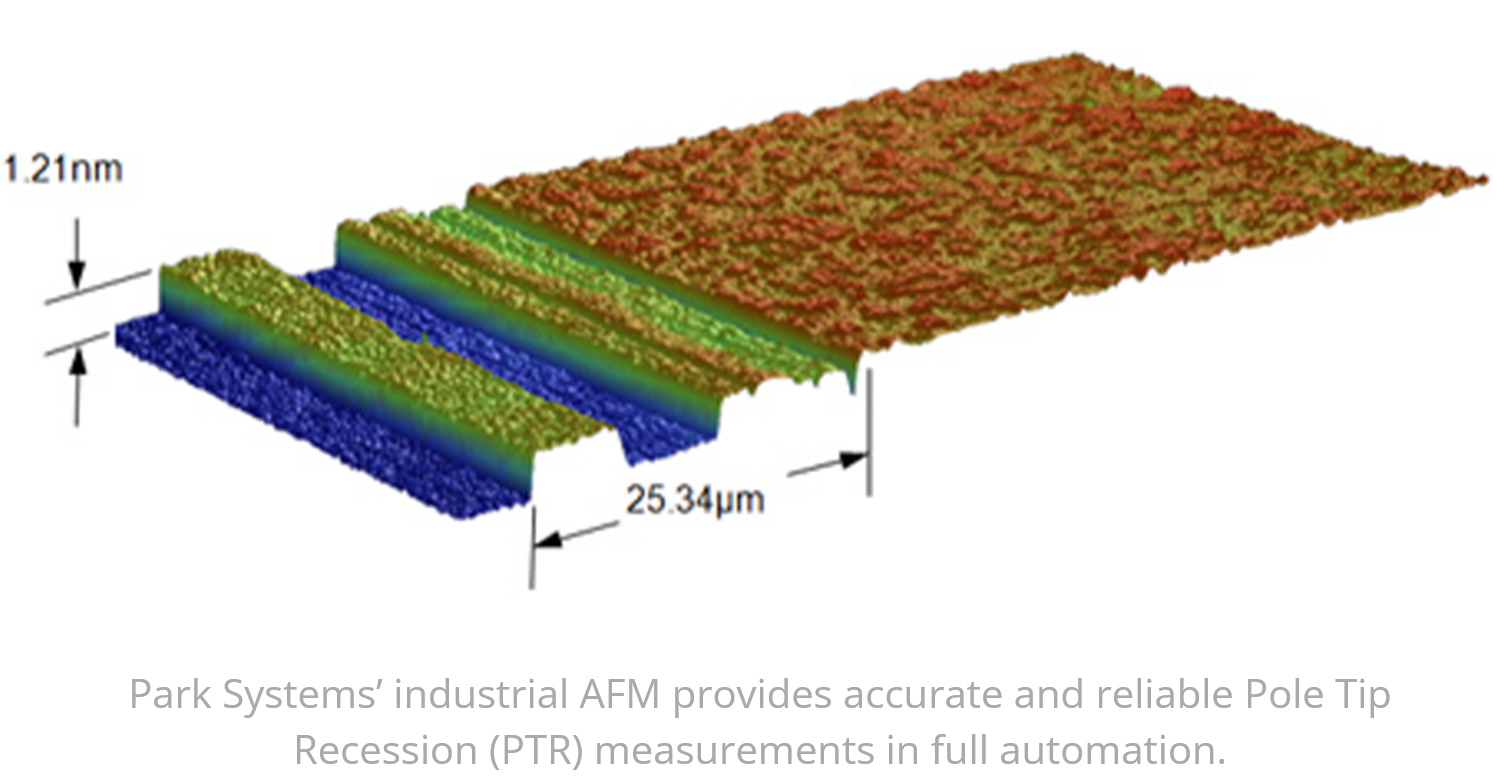

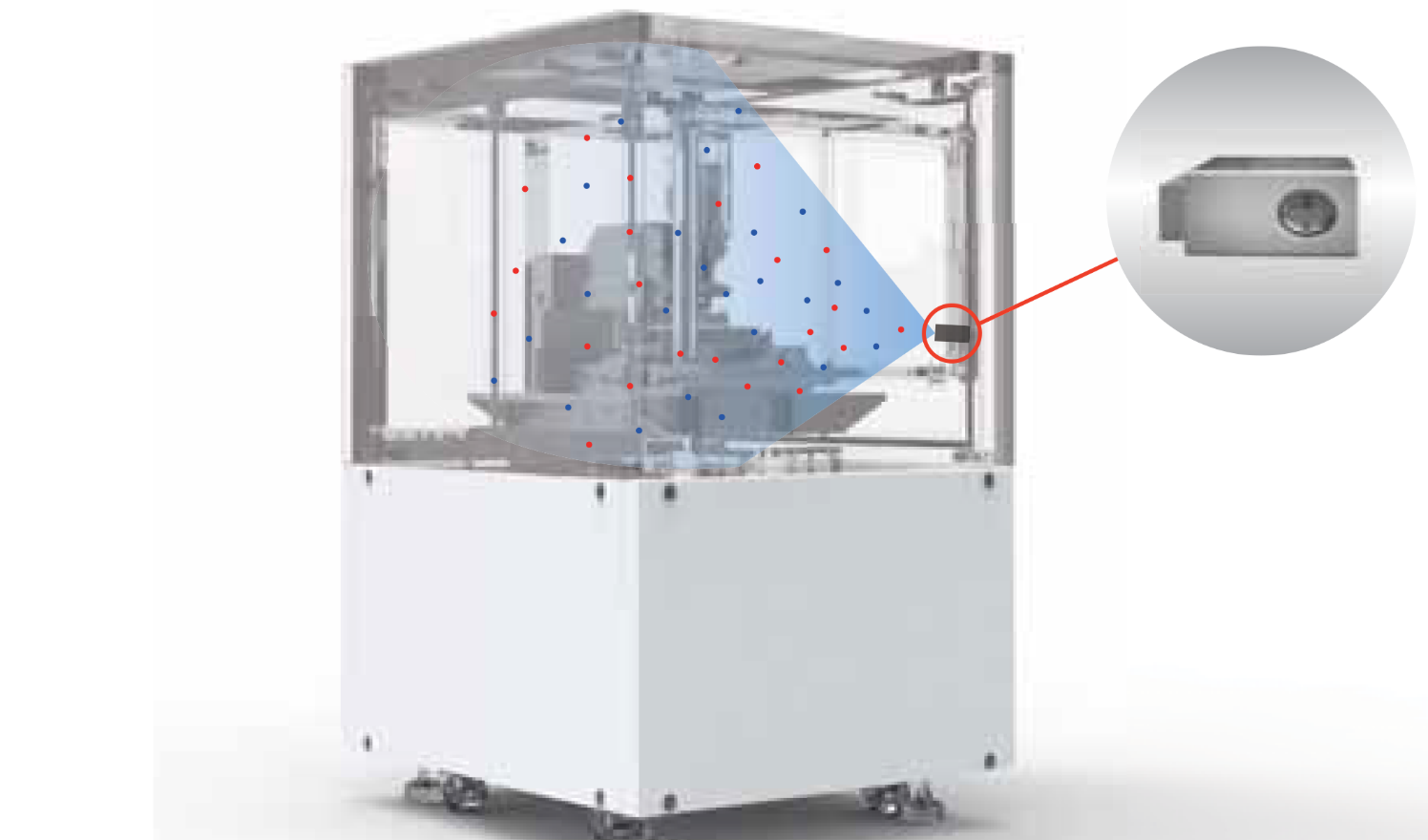

Park Systems' PTR Series is a fully automatic

industrial in-line AFM solution for, but not limited to,

automatic Pole Tip Recession measurements on

Rowbar-level, individual Slider-level, and HGA-level

sliders. With sub-nano scale accuracy, repeatability,

and throughput, the PTR Series is the metrology tool

of choice for Slider manufacturers to improve their

overall production yield.

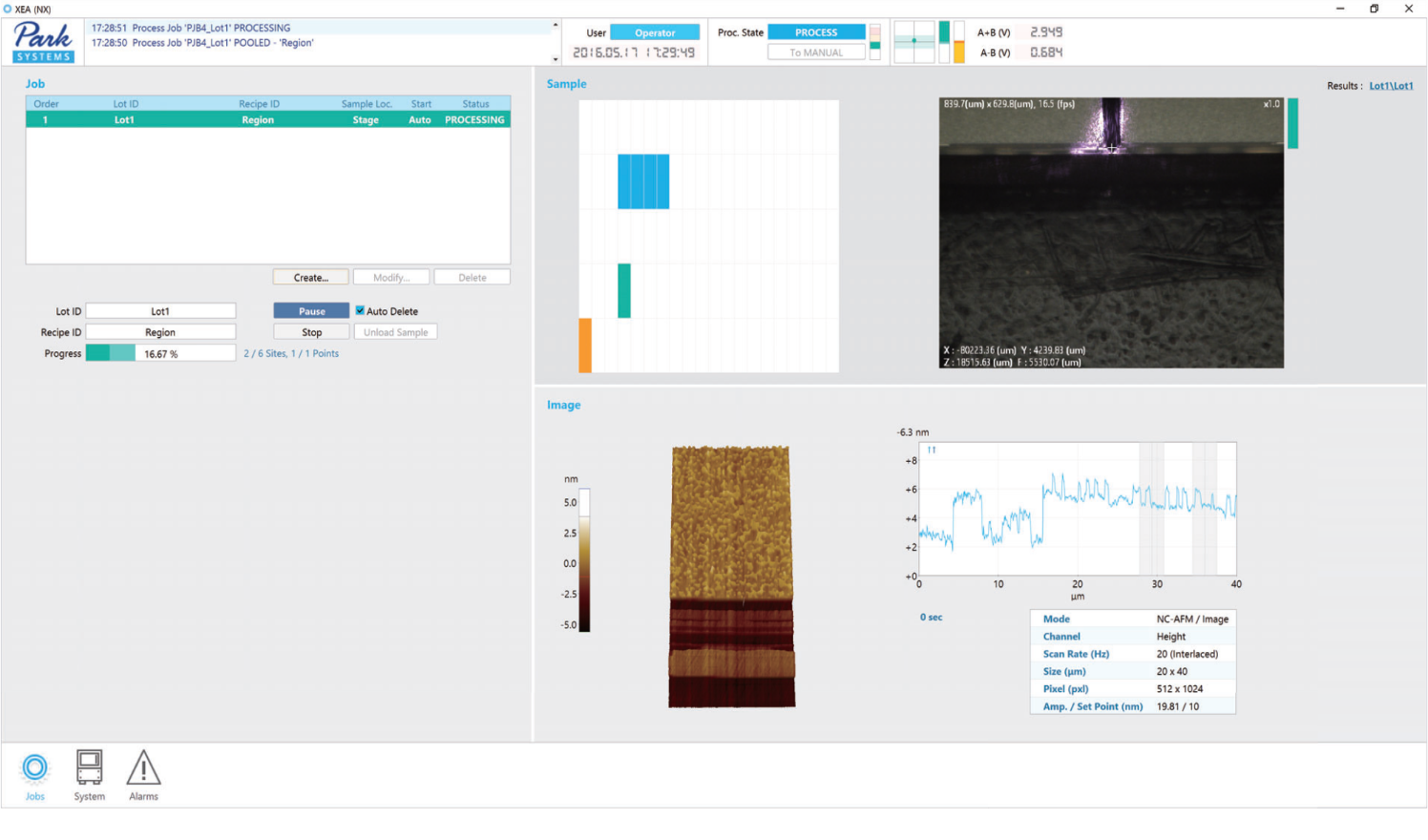

Fully Automated AFM for In line

Hard Disk Slider Metrology

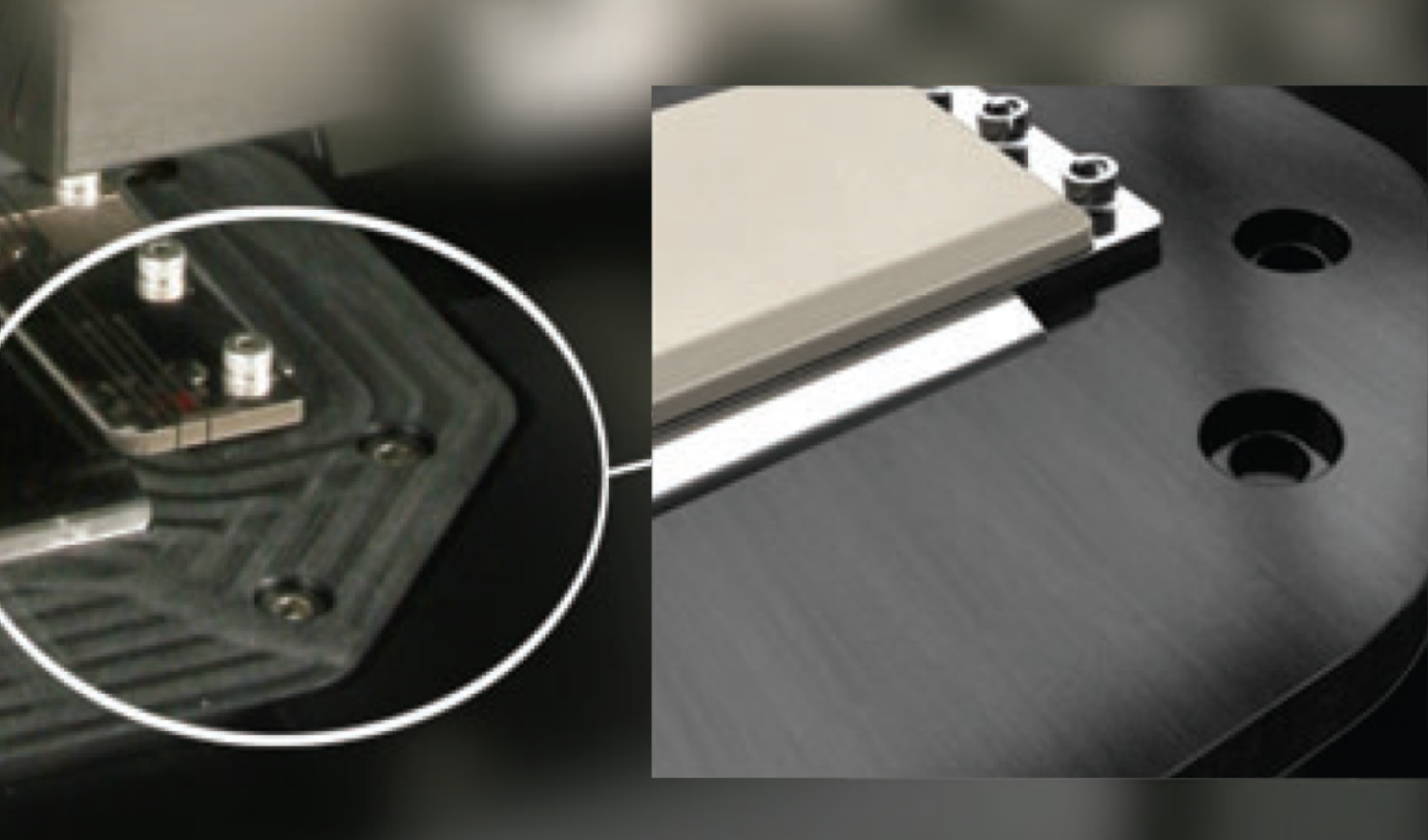

- Automated PTR imaging in non-contact mode

- Automated analysis of PTR images for carrier, rowbar, or individual slider

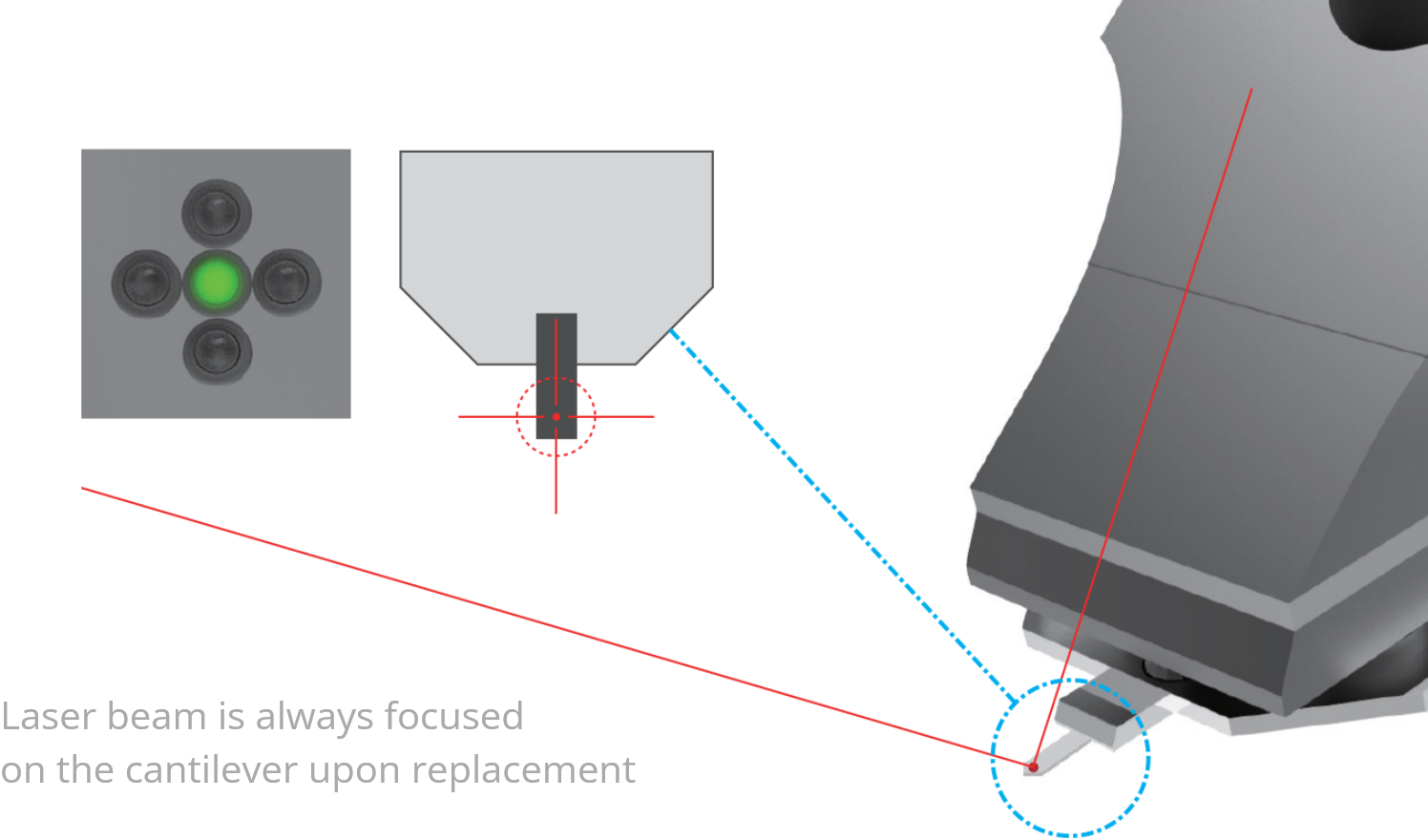

- Automatic tip exchange (optional)

- Industry's lowest system noise of less than 0.5 Arms

Accurate and Repeatable

Measurements for Improved

Production Yield

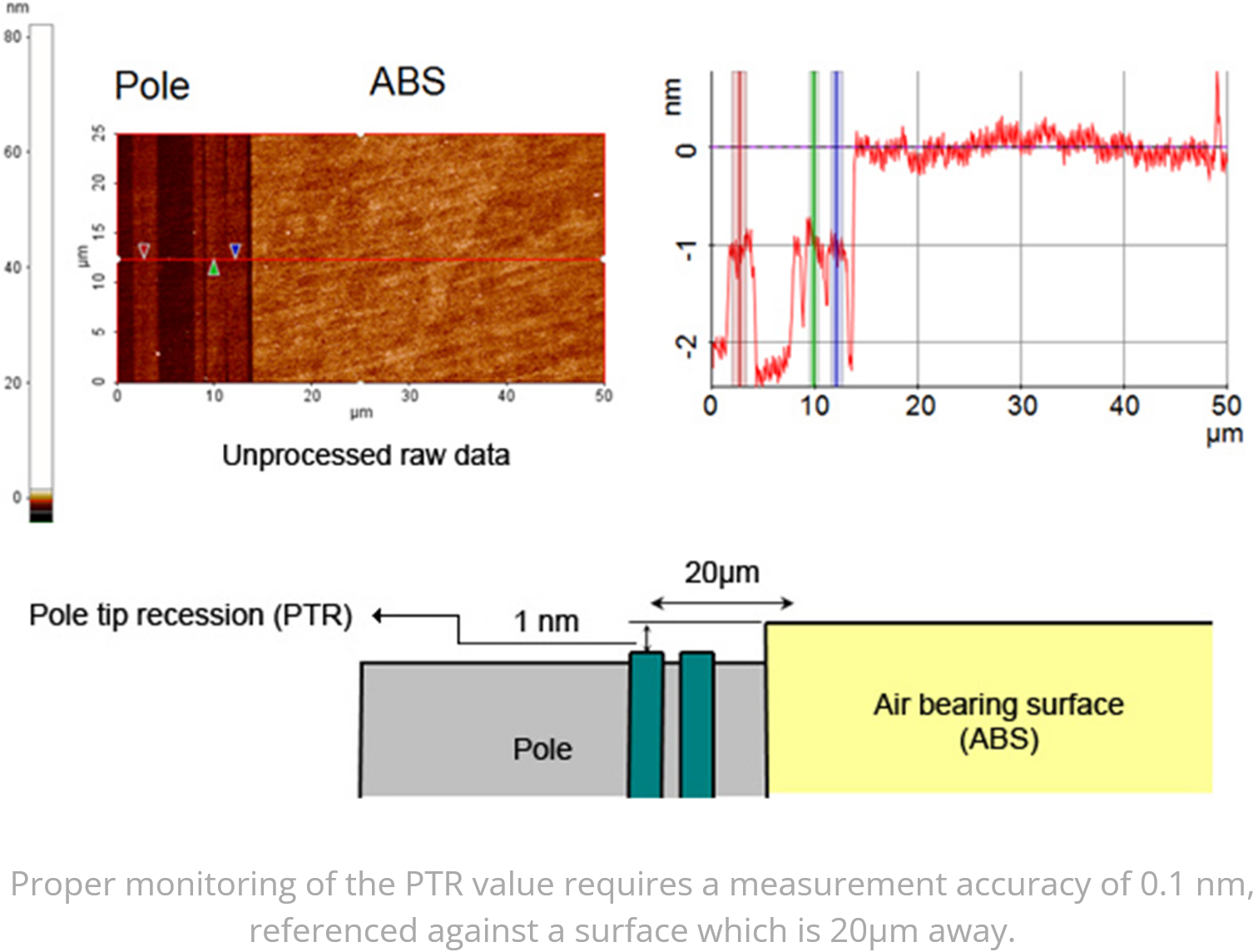

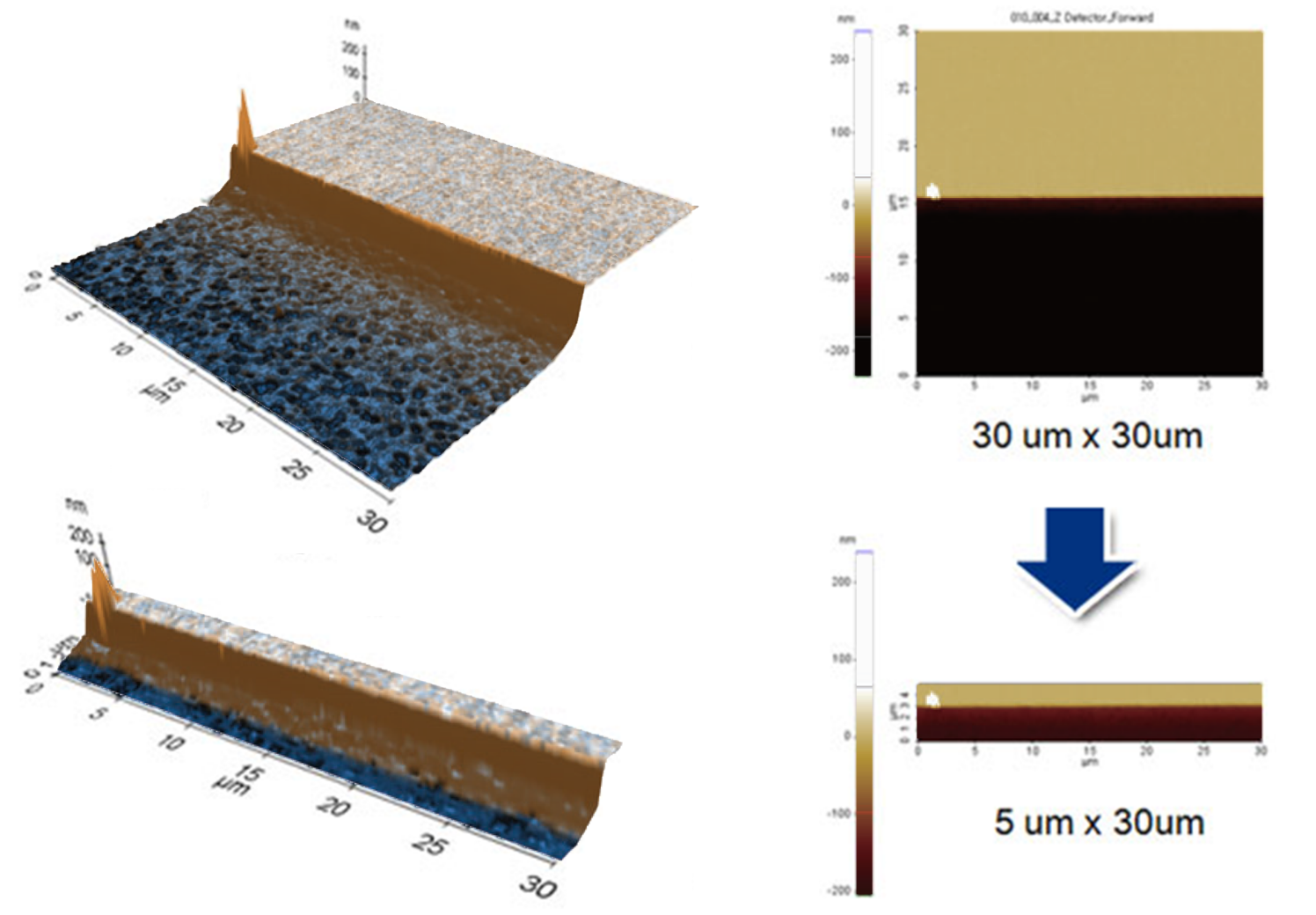

- Accurate imaging of HDD sliders without any need of larger sized reference scans

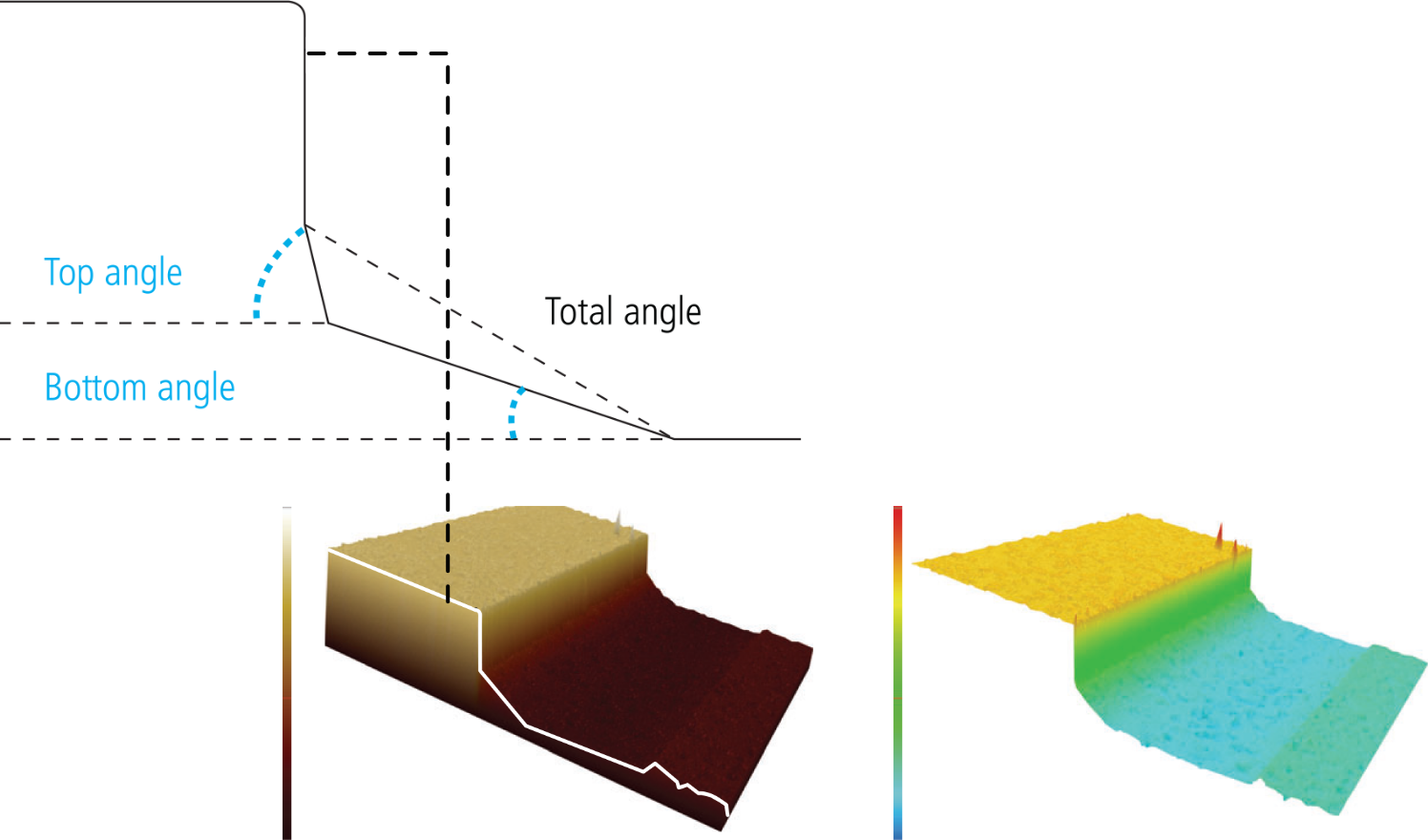

- Accurate height and angle measurements for industry leading PTR gauge repeatability

- Flat and orthogonal XY scan removes artifacts from background curvature

- Superior tool-to-tool matching

Accurate Height Measurements

with Low Noise Z Detector

- True Sample TopographyTM without edge overshoot or piezo creep error

- Accurate surface height recording, even during high-speed scanning

- Industry leading forward and backward scan gap of less than 0.15%

Best Tip Life and Scan Resolution by

True Non-Contact™ Mode

- 1 0 times or longer tip life during PTR measurements than any other AFMs

- Minimal tip wear from prolonged high-quality scans

- Minimized sample damage or modification