Low Noise, High Throughput Atomic Force Profiler

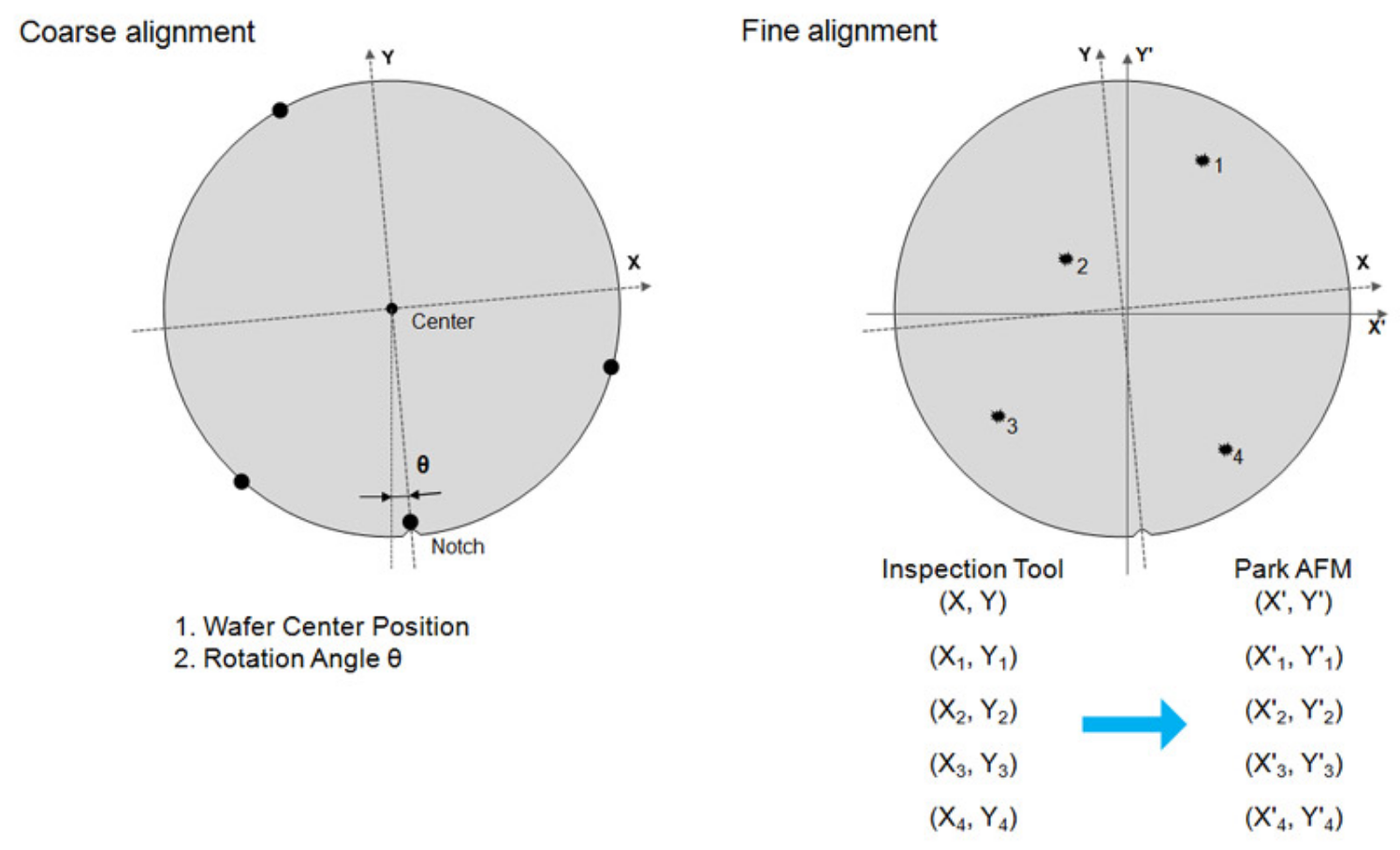

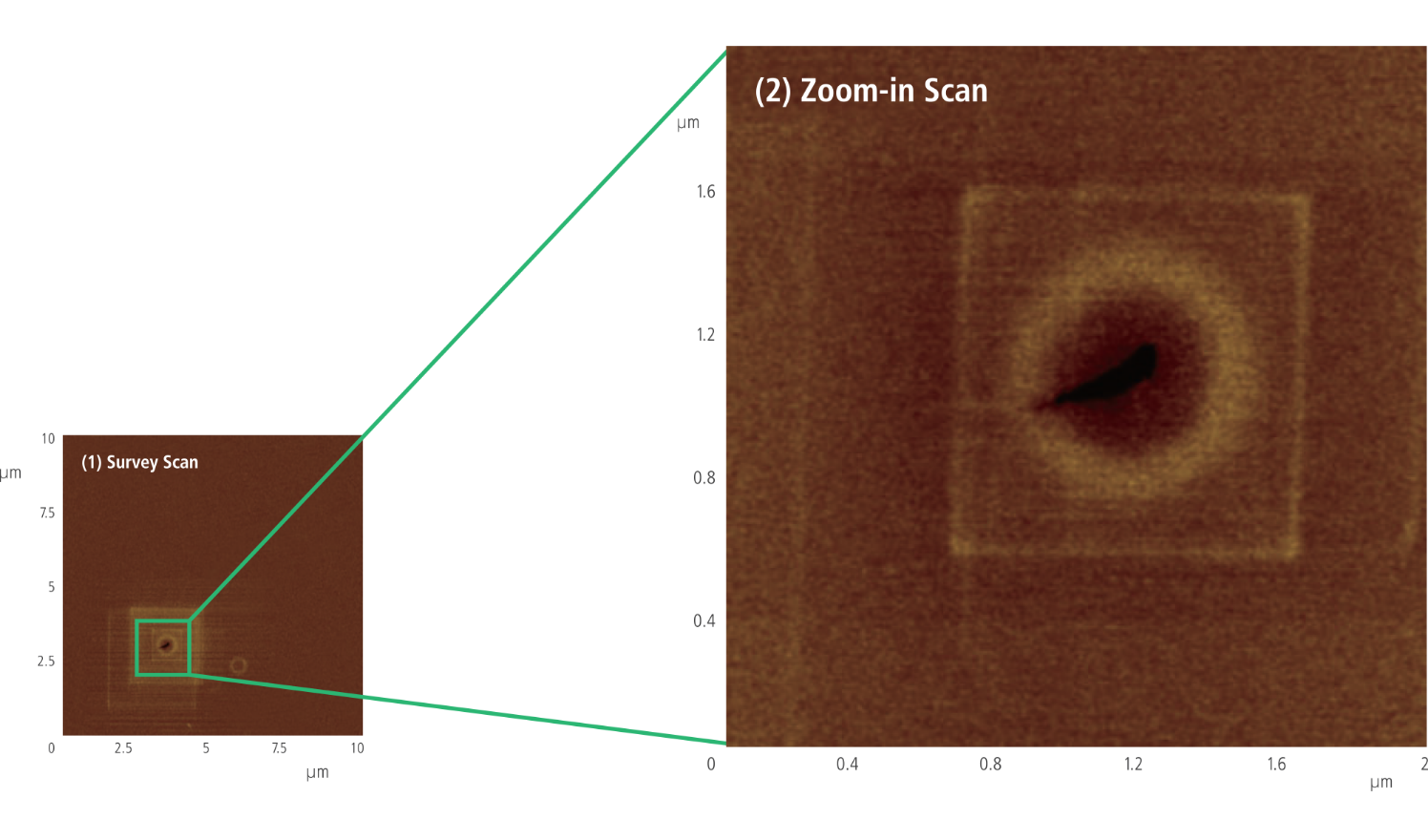

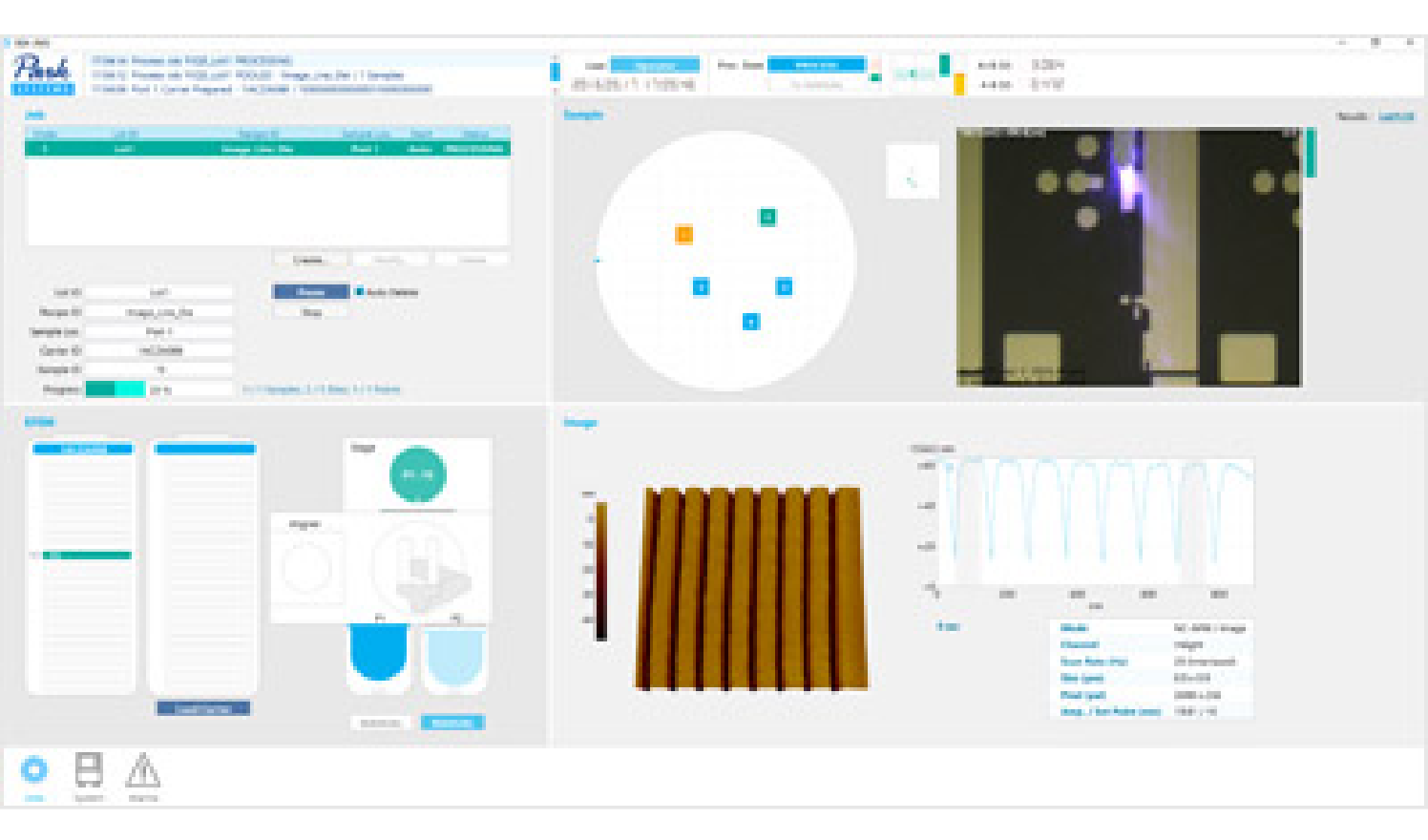

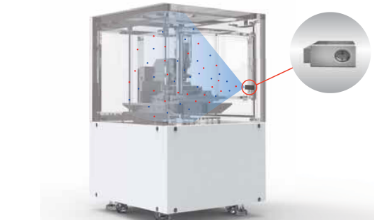

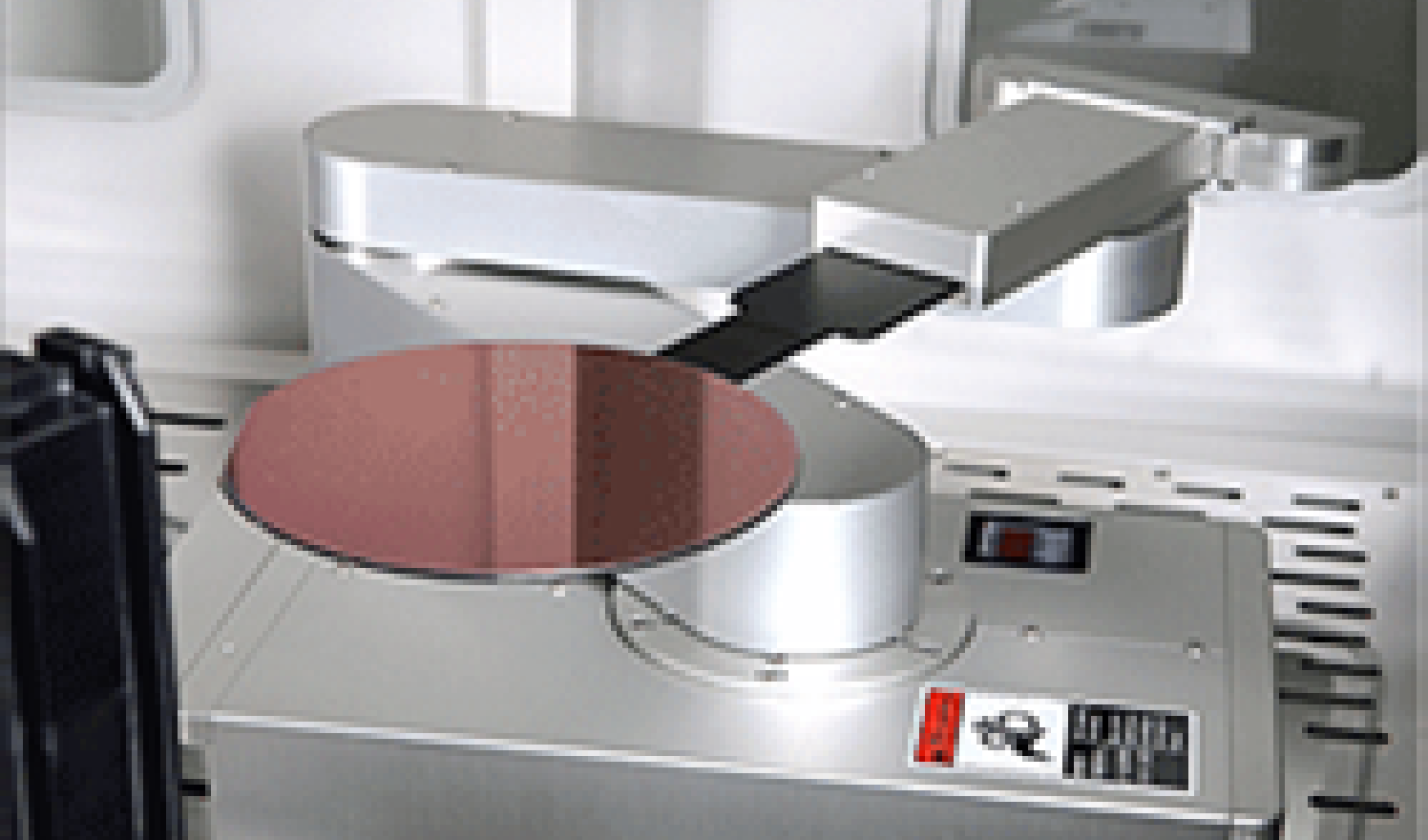

Park NX-Wafer is the industry’s leading automated AFM metrology system for semiconductor and related fabrications. It provides wafer fab inspection and analysis, automatic defect review for bare wafers and substrates, and CMP profile measurements. Park NX-Wafer has the highest nanoscale surface resolution with sub-angstrom height accuracy, scan after scan with negligible tip to tip variation and preserved tip sharpness unmatched by others. Park NX-Wafer with its automated system features including auto tip exchanger, live monitoring, target positioning without reference marks and auto analysis makes the best semiconductor AFM tool in the industry.

- Low noise atomic force profiler for more accurate CMP profile measurements

- Sub-Angstrom surface roughness measurements with extreme accuracy and negligible tip-to-tip variation

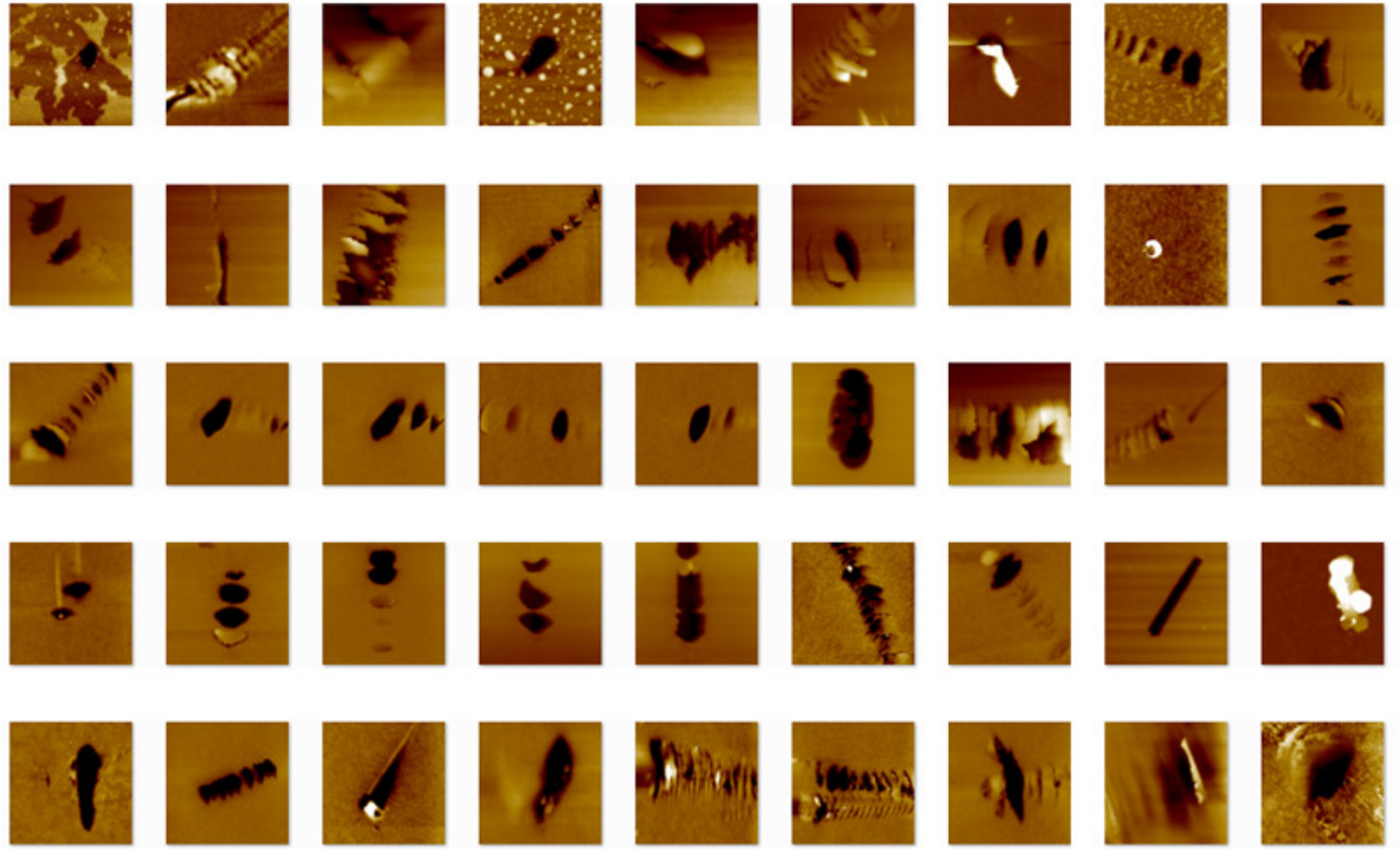

- Fully automated AFM solution for defect imaging and analysis

- A fully automated system with auto tip exchange, robot wafer handler

- Capable of scanning 300 mm wafers